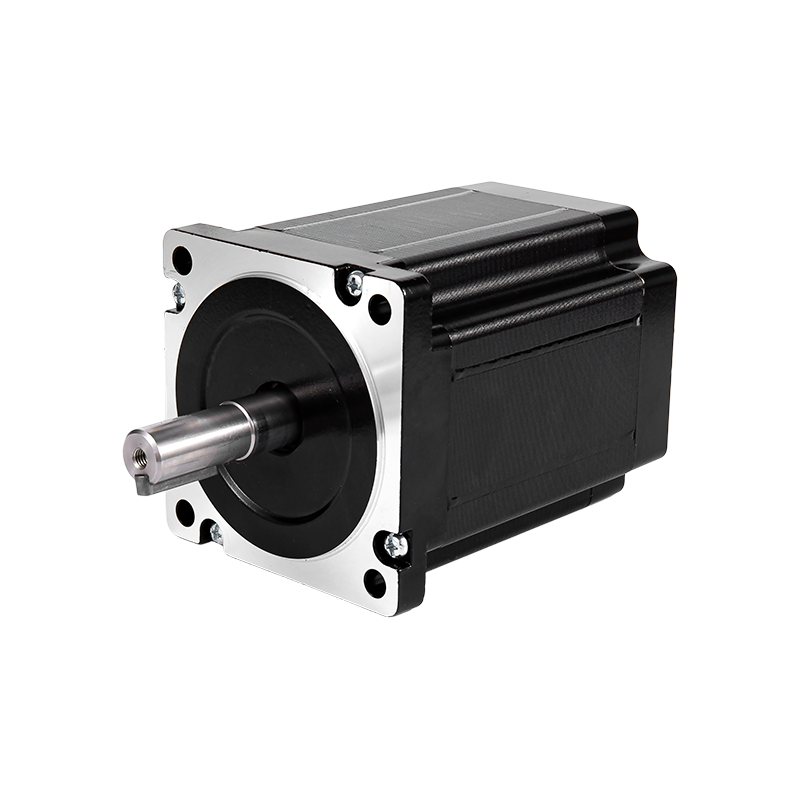

NEMA 34 Stepper: Maximum Torque and Industrial Strength

The NEMA 34 stepper motor, with its 3.4 inch (approx. 86mm) square face, is the choice for extremely high-torque requirements, serving as the power core for large-scale automation and heavy machinery.

These motors deliver continuous holding torque ranging from 4.0 Nm up to 15 Nm or more, making them comparable to many low-end servo systems in static and low-speed performance. The substantial mass and volume of the NEMA 34 allow for high thermal tolerance and the accommodation of robust, large-diameter shafts, ensuring mechanical integrity under high load. They are used when maximum force is required without the complexity of a servo drive system.

Introduction

Detailed Parameters and Performance Data

RETEK: Heavy-Duty Positioning and Indexing Power

Suzhou Retek Electric Technology Co., Ltd. focuses on maximizing the torque output and mechanical reliability of the NEMA 34 series. Our engineers optimize the magnetic field and winding geometry to achieve the highest possible static torque, which is essential for large gantry systems, plasma cutters, and heavy indexing tables. We guarantee the structural integrity and vibration dampening necessary for high-inertia load movement.

Applications

Advanced Technology Highlights

Heavy Industrial Applications for NEMA 34 Stepper Motors

- Large Gantry Systems and Plasma/Water-Jet Cutters: Driving large, heavy moving axes. Challenge: Overcoming high inertia and frictional forces.

- Automated Storage and Retrieval Systems (AS/RS): Positioning large vertical or horizontal loads in warehouses.

- Indexing and Rotary Tables: High-torque rotation for welding positioners and multi-axis jigs.

- Large Valve and Damper Actuators: Requiring very high torque to operate large, high-pressure fluid control systems.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters (NEMA 34 Series)

| Parameter | Range / Typical Value | Unit |

| Frame Size (NEMA) | 34 (86mm) | Standard |

| Holding Torque | 4.0 to 15.0+ | Nm |

| Steps per Revolution | 200 | Steps |

| Phase Current (Rated) | 3.0 to 8.0 | A |

| Rotor Inertia | High (relative to size) | kg ⋅ m$^2$ |

Additional Information

Supplementary Details & Notes

Integrated Production and Customization Workflow

The manufacturing process for NEMA 34 motors involves high-precision rotor-stator alignment and meticulous coil bracing to prevent movement under high vibration. The motor's thermal performance is validated via sustained load testing.

- Shaft Customization: Customizing the shaft with a keyway, specific thread, or double-ended design to support a brake or encoder on the non-drive end.

- Winding Optimization: Tailoring the winding to match specific industrial drive voltages and current limits, maximizing performance within the client's system constraints.

- Integrated Brakes: Factory installation of a high-torque safety brake unit (spring-applied, power-off type) for vertical axis or emergency stop compliance.

- Connector Upgrades: Providing specific IP-rated industrial connector solutions (e.g., M23 power and signal connectors) for fast, reliable field wiring.

About Jiangsu Retek Motion Co., Ltd.

As China Nema 34 Stepper Motor 86mm High Torque Stepping Motor Manufacturers and Wholesale Nema 34 Stepper Motor 86mm High Torque Stepping Motor OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español