High Performance NEMA 23: Boosting Dynamic Torque

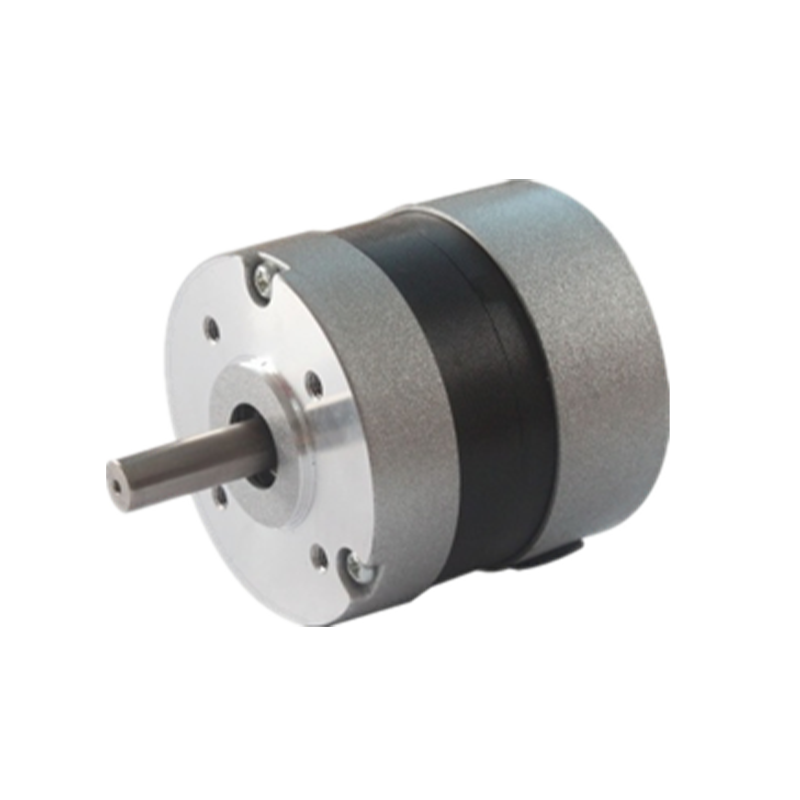

The High Performance NEMA 23 Stepper Motor is a premium version of the standard 57mm frame, specifically engineered to maximize usable torque, particularly at higher speeds (>300 RPM).

This is typically achieved through one of three methods: 1) Longer Stack Length (increasing torque density); 2) Lower Inductance Winding (improving high-speed performance); and 3) Higher Energy Magnets. These motors are paired with high-voltage (e.g., 48V to 80V) stepper drivers to ensure maximum current is forced into the windings quickly, overcoming inductance and delivering peak torque over a wider speed range than standard NEMA 23 motors.

Introduction

Detailed Parameters and Performance Data

RETEK: Max-Torque Solutions for High-Speed Automation

Suzhou Retek Electric Technology Co., Ltd. provides the High Performance NEMA 23 series for machine builders seeking to maximize throughput and gantry speed without transitioning to a full servo system. Our motors use optimized lamination geometry and high-grade materials to minimize hysteresis losses, ensuring the motor runs cooler and more efficiently when driven at high frequencies. This series is the cost-effective answer to boosting the speed and power of mid-sized CNC and automated assembly equipment.

Applications

Advanced Technology Highlights

Demanding Applications for High Performance NEMA 23

- High-Speed CNC Routers: Driving X/Y axes at high feed rates (e.g., >1000 mm/s) where standard steppers would experience severe torque drop-off. Challenge: Maintaining torque at high velocity.

- High-Acceleration Indexing Tables: Requiring rapid movement and settling time in automated assembly lines.

- Large-Scale 3D Printing (Industrial): Actuators for large, fast-moving gantries used in industrial additive manufacturing.

- High-Throughput Packaging: Motors for fast-moving label applicators, flying shear systems, and bottle filling.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters (High Performance NEMA 23)

| Parameter | Range / Typical Value | Unit |

| Frame Size (NEMA) | 23 (57mm), Long Stack | Standard |

| Holding Torque | Up to 4.0 | Nm |

| Inductance per Phase | $ < 5$ | mH (Optimized Low) |

| Recommended Voltage | 48 to 80 | VDC Bus |

| Current per Phase | 3.0 to 6.0 | A |

Additional Information

Supplementary Details & Notes

Integrated Production and Customization Workflow

Production includes advanced testing to measure the dynamic torque curve across the full speed range, ensuring the motor meets the high-performance benchmark. Thermal mapping is performed under extreme conditions.

- Custom Shaft Features: Hardened output shafts with a precise keyway or spline, designed to withstand the high torque output.

- Integrated Cooling: Offering a custom-designed rear flange that allows for a bolt-on cooling fan to maximize continuous torque in high-ambient-temperature environments.

- Winding Tuning: Extreme low-inductance winding customization for specific high-speed applications (>1500 RPM).

- Encoder/Brake Integration: Factory mounting of high-resolution encoders and/or high-torque electromagnetic holding brakes.

About Jiangsu Retek Motion Co., Ltd.

As China High Performance Nema 23 Stepper Motor 57mm Manufacturers and Wholesale High Performance Nema 23 Stepper Motor 57mm OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español