Bevel Gear Stepper Motor: Right-Angle, High-Torque Indexing

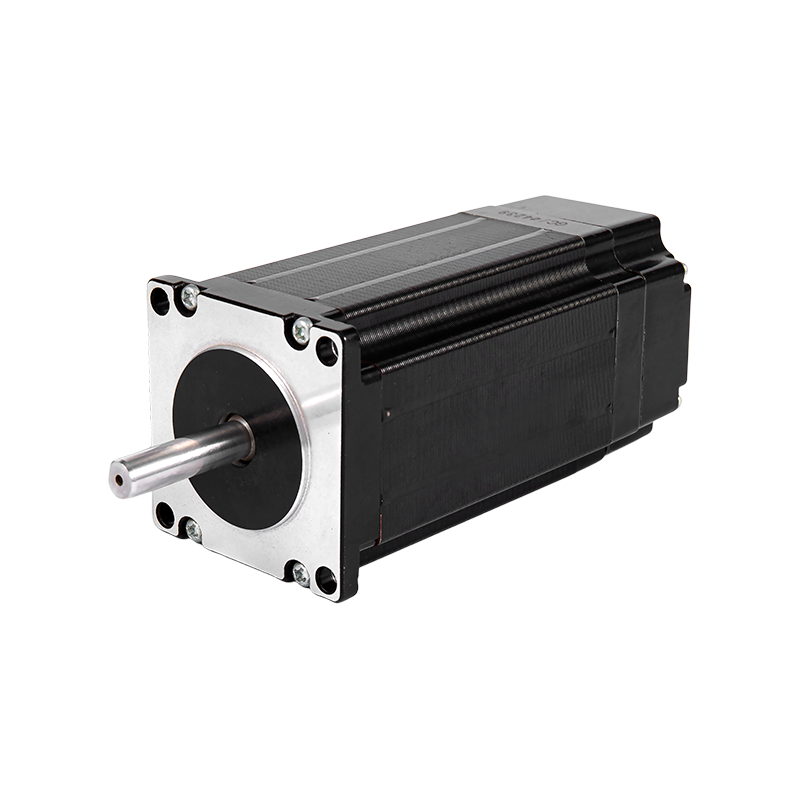

The Right Angle Bevel Gear Stepper Motor combines a standard stepper motor (e.g., NEMA 23 or 34) with a compact, right-angle bevel gearhead.

This design provides a high-torque, indexed drive with an output shaft that is perpendicular to the motor shaft. Unlike worm gears, bevel gears rely on rolling contact, making them highly efficient (typically >90%) and reversible (no self-locking). They are ideal for applications requiring high precision and efficiency in a right-angle configuration, often found in machine tools and conveyor systems where space saving is critical.

Introduction

Detailed Parameters and Performance Data

RETEK: High-Efficiency Right-Angle Drives for Automation

Suzhou Retek Electric Technology Co., Ltd. provides bevel gear solutions for dynamic indexing where speed and efficiency are key. We use high-precision, spiral bevel gears (rather than straight bevel) which offer smoother, quieter operation and higher torque transmission. We ensure the gearbox has minimal backlash, maintaining the excellent positional accuracy of the input stepper motor.

Applications

Advanced Technology Highlights

Efficient Right-Angle Drive Applications for Bevel Gears

- Automated Machine Tools: Drives for indexing turrets, tool changers, and positioning in compact machining centers. Challenge: High efficiency and fast, accurate indexing.

- Conveyor Systems: Right-angle drives for belt turn modules or vertical lift systems.

- Printing and Packaging: Accurate right-angle synchronization of rollers or applicators.

- Industrial Mixers/Agitators: Drives requiring a high-efficiency right-angle torque input.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters (Bevel Gear Stepper)

| Parameter | Range / Typical Value | Unit |

| Input Motor | NEMA 23 to 42 | Standard |

| Gearbox Type | Spiral Bevel Gear (Right Angle) | Design |

| Reduction Ratio | 1:1 to 5:1 (Typical) | Ratio |

| Efficiency | >90% | Percentage |

| Backlash | Standard or Low Backlash (Arc-min) | Feature |

Additional Information

Supplementary Details & Notes

Production & Customization Services

Production involves rigorous gear pair matching and running tests under load to verify gear meshing patterns and minimize acoustic noise.

- Integrated Planetary Stage: Factory mounting of a low-backlash planetary stage before the bevel gear to achieve higher overall reduction ratios.

- Output Shaft: Providing custom hollow-bore, double-ended, or integrated flange outputs for direct connection to machine components.

- Low Backlash Tuning: Custom tuning and measurement to achieve ultra-low backlash (e.g., <3 arc-minutes) for demanding indexing tasks.

- Sealing/IP Rating: Enhancing seals to achieve IP65 rating, common in industrial washdown environments.

About Jiangsu Retek Motion Co., Ltd.

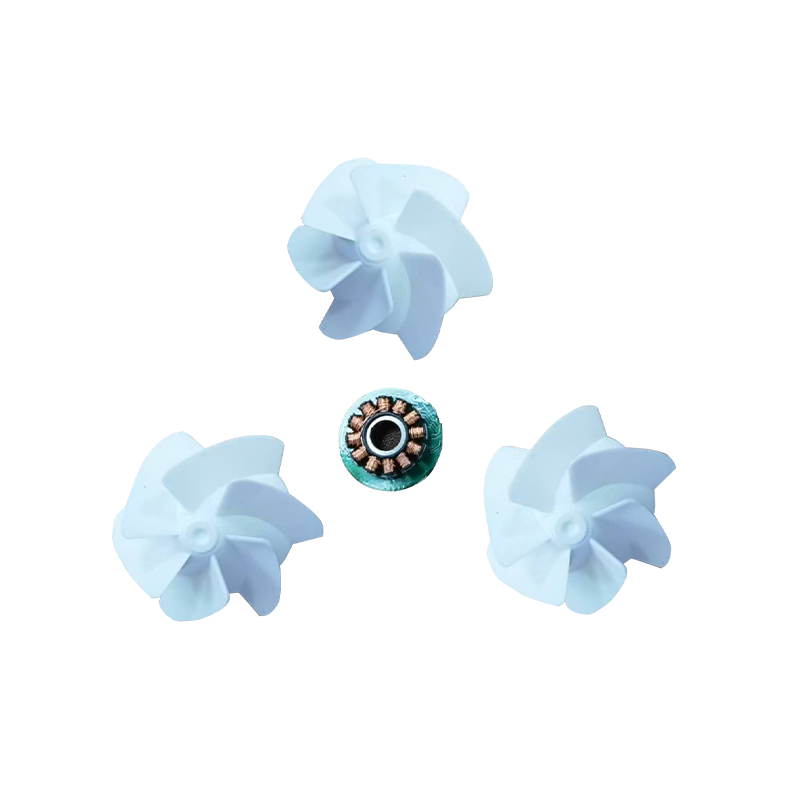

As China High Torque Stepper Motor Gearbox Right Angle Bevel Gear Manufacturers and Wholesale High Torque Stepper Motor Gearbox Right Angle Bevel Gear OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español