High Torque BLDC Motor Technical Overview

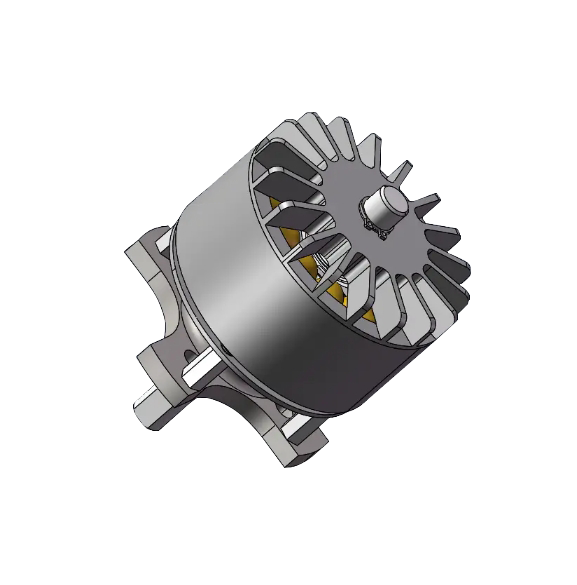

These BLDC motors are engineered for applications demanding a high rotational force output within a compact structure. The design prioritizes magnetic circuit optimization, often incorporating high-energy density Rare-Earth Magnets (NdFeB, N45 grade or higher) and concentrated winding topology. This configuration increases the effective flux density by up to 15% compared to standard designs, directly resulting in enhanced torque output and superior acceleration capabilities. The controllers integrate advanced Field-Oriented Control (FOC) or trapezoidal commutation logic to maintain stable torque across the entire speed range, specifically benefiting starting conditions and heavy-load transitions. Operating voltage ranges are typically optimized for 24VDC to 48VDC industrial standards, ensuring broad compatibility with common power supply architectures, with specific models available up to 310VDC for high-power applications.

- Focus Area: High starting torque, sustained load handling, and power-to-volume ratio.

- Key Technology: Optimized stator slot filling, high-grade magnetic materials, and low inductance windings to maximize current rise time.

- Thermal Management: Robust housing designs with integrated heat fins or provision for liquid cooling interface to dissipate heat efficiently and maintain performance stability under continuous high load.

- Magnetic Circuit: Typically utilizes a 12-slot, 10-pole or similar high-pole-count configuration to increase the number of magnetic flux reversals per revolution, boosting torque.

Introduction

Detailed Parameters and Performance Data

Introduction to Torque-Optimized Motor Solutions

Developing dependable motion control systems requires components that can deliver precise and substantial power under varied, often harsh, loads. This series of high torque motors is a product of focused engineering on power density and long-term reliability. As a leading manufacturer specializing in industrial and specialized electric motor technology, Suzhou Retek Electric Technology Co., Ltd. (RTK) focuses on supplying OEM clients with drive systems that minimize downtime and maximize operational output in demanding industrial, material handling, and robotic environments.

Our production methodology integrates automated stator winding and meticulous magnet assembly processes under strict quality control, ensuring winding uniformity and consistent performance across all units designed for high-load cycles. We provide comprehensive technical support from initial prototyping to final volume production.

Applications

Advanced Technology Highlights

Key Application Areas

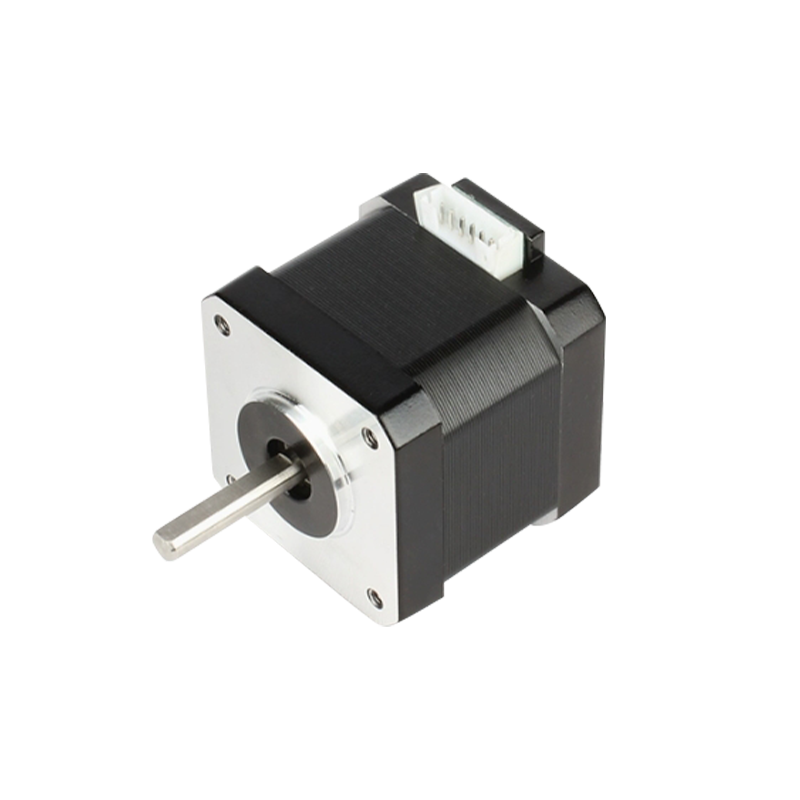

- Industrial Robotics (Heavy Payloads): Joint actuation, base rotation, and manipulator movement requiring high holding torque and dynamic stiffness.

- Material Handling Systems: High-acceleration conveyor belt drives, Automated Guided Vehicles (AGVs) requiring rapid start/stop, and heavy-duty lifting equipment.

- High-Force Electric Actuators: Precision valve control in petrochemical plants, heavy gate openers, and industrial presses.

- Renewable Energy Systems: Solar panel tracking (Heliostats) requiring substantial torque to overcome wind load.

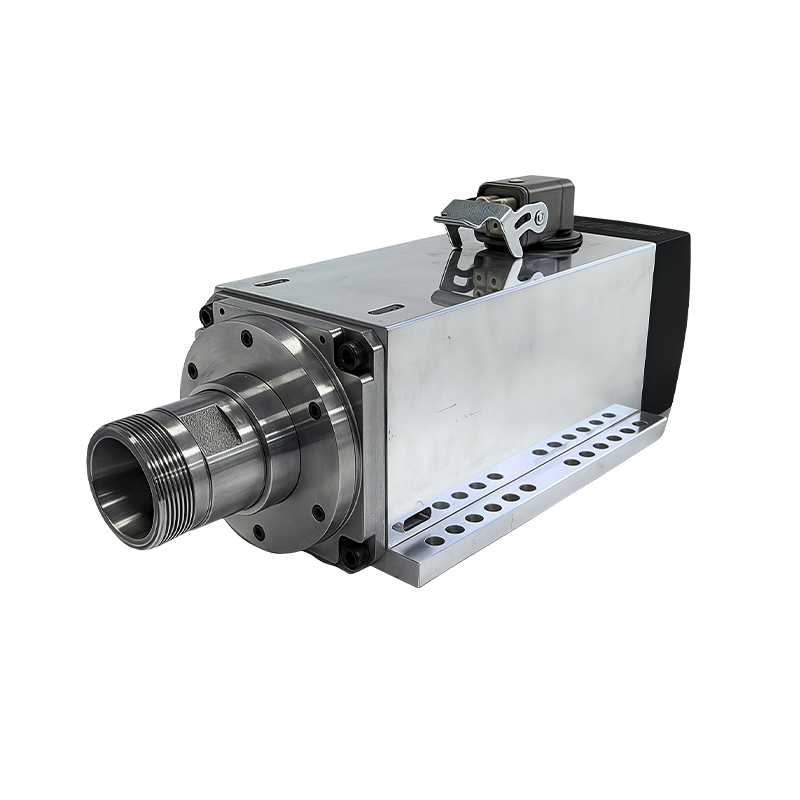

- Specialized Power Tools: High-torque demolition hammers, specialized construction tools, and industrial mixers.

- Electric Vehicles (Low Speed/High Load): Small electric utility vehicles and golf carts.

Technical Specifications

Industrial & Commercial Usage

Selected Motor Specifications

Specifications are dependent on specific frame size, but the core characteristic is the high Kt (Torque Constant) value.

| Parameter | Example BL76 Series (High Torque Variant) | Example BL112 Series (Heavy Duty) |

| Rated Torque (Nm) | 1.2 - 2.5 | 4.0 - 6.5 |

| Rated Power (W) | 300 - 800 | 800 - 1500 |

| Rated Voltage (VDC) | 24 / 48 | 48 / 96 |

| Torque Constant (Kt Nm/A) | 0.12 - 0.25 | 0.30 - 0.50 |

| Motor Inertia (g⋅cm2) | 400−800 | 1500−3000 |

| Peak Current (A) | 30 | 55 |

Additional Information

Supplementary Details & Notes

Manufacturing Process and Customization Services

Our manufacturing facility utilizes advanced production lines focused on minimizing winding variability and ensuring consistent air gap tolerances. Each motor undergoes automated End-of-Line (EOL) testing for back-EMF, winding resistance, and torque characteristics under load before shipment.

- Shaft Modification: Custom shaft lengths, diameters, keyways, spline options, and specialized coatings (e.g., black oxide) are available upon request.

- Winding Customization: We offer specific Kv and torque constant tuning to meet unique application speed and power requirements, including options for delta (Δ) or wye (Y) winding configurations.

- Encoder/Brake Integration: Motors can be fitted with integrated fail-safe holding brakes, multi-turn absolute encoders, or high-resolution inductive sensors for specialized motion control.

- Environmental Sealing: Capabilities for meeting specific IP ratings, including full encapsulation of windings and specialized sealing for connectors and shaft egress.

- Controller Matching: Provision of pre-tuned, matched motor control electronics to guarantee optimal system performance out-of-the-box.

About Jiangsu Retek Motion Co., Ltd.

As China High Torque Brushless DC Motors Manufacturers and Wholesale High Torque Brushless DC Motors OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español