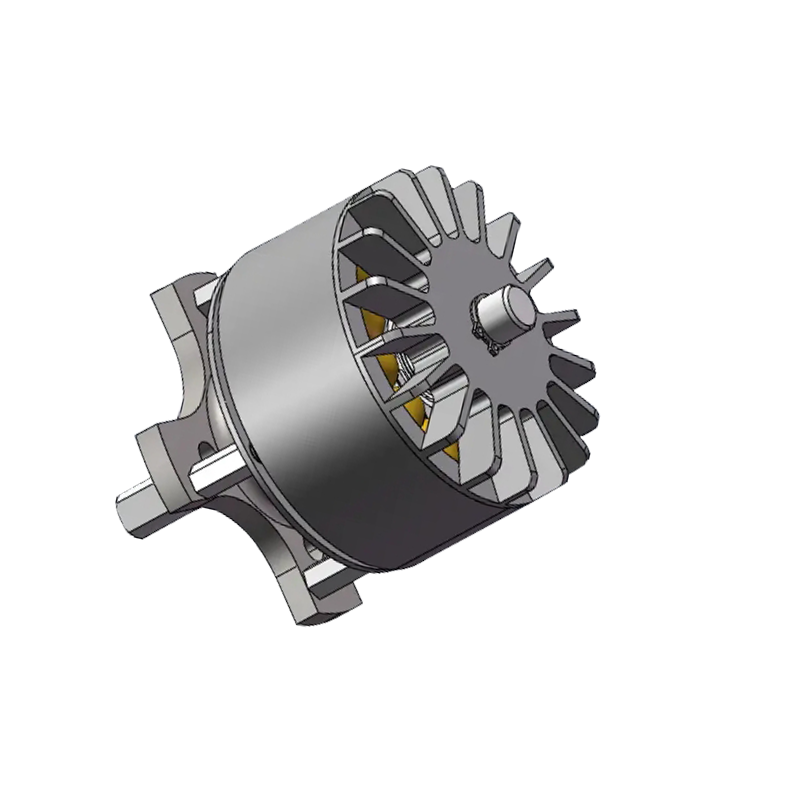

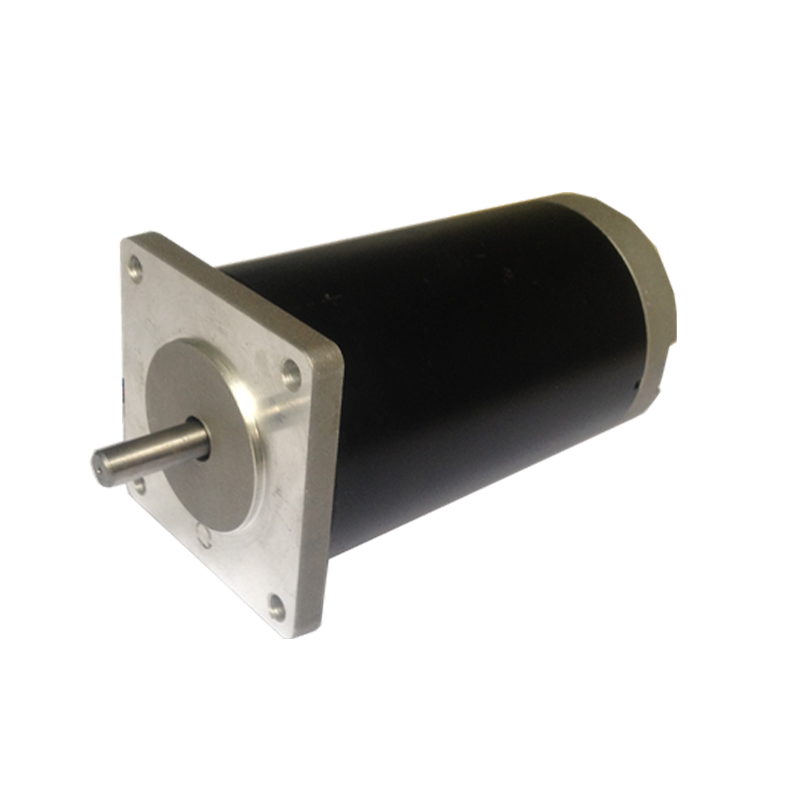

NEMA 17 Stepper: The Standard for Cartesian Motion Systems

The NEMA 17 stepper motor, with its 1.7 inch (approx. 42mm) square face, is the most ubiquitous stepper frame size in desktop automation.

We offer both the standard 1.8∘ (200 steps/rev) and the high-resolution 0.9∘ (400 steps/rev) variants. The choice depends on the required positional resolution versus the motor's speed capability. The 0.9∘ version offers twice the native resolution, resulting in smoother micro-stepping and better positional accuracy, but typically comes with a slight reduction in maximum speed/torque. The NEMA 17 is a balanced design, offering high holding torque while maintaining a compact form factor suitable for moving gantries and medium-duty positioning stages.

Introduction

Detailed Parameters and Performance Data

RETEK: Optimized Stepper Performance for Automation

Suzhou Retek Electric Technology Co., Ltd. provides NEMA 17 motors optimized for low-inductance windings, allowing higher current rise rates and thereby extending the motor's useful torque range at higher stepping speeds. Our motors are widely integrated into CNC routers, laser engravers, and medical dispensing machines worldwide. We focus on low detent torque (unpowered holding torque) to minimize mechanical resistance, which is critical for systems with external load forces.

Applications

Advanced Technology Highlights

Key Applications for NEMA 17 Stepper Motors

- Desktop CNC and Milling Machines: Motors for X, Y, and Z axes for light to medium cutting loads. Challenge: Balancing holding torque and high-speed capability.

- Pick-and-Place Robotics: Actuators for linear slides and rotational grippers requiring precise indexing.

- Lab Equipment: Syringe pumps, automated microscopes, and fluid sampling devices.

- Commercial Vending Machines: Drive mechanisms for item dispensing.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters (NEMA 17 Series)

| Parameter | Range / Typical Value | Unit |

| Frame Size (NEMA) | 17 (42mm) | Standard |

| Step Angle Options | 0.9 or 1.8 | Degrees |

| Holding Torque | 0.3 to 0.8 | Nm |

| Rotor Inertia | Optimized Low | g ⋅ cm$^2$ |

| Voltage Compatibility | Bipolar Drive (12V to 48V Bus) | Type |

Additional Information

Supplementary Details & Notes

Integrated Production and Customization Workflow

Production includes low-friction bearing selection and precise stack alignment. Final testing involves measuring the phase inductance, resistance, and step-angle accuracy under load.

- Lead Screw Integration: Factory mounting of precision leadscrews (e.g., T8 trapezoidal) with anti-backlash nuts for integrated linear actuators.

- Winding Customization: Offering high-voltage/low-current windings (for long cable runs) or low-voltage/high-current windings (for maximum torque).

- Integrated Dampers: Providing optional motor dampers (mass-spring systems) to reduce resonant vibration and audible noise during mid-range stepping.

- Connector Options: Customizing connector types (e.g., Molex, JST, or industrial M12) and cable harness length for plug-and-play assembly.

About Jiangsu Retek Motion Co., Ltd.

As China Nema 17 Stepper Motor 42mm Step Motor 0.9 deg 1.8 Deg Manufacturers and Wholesale Nema 17 Stepper Motor 42mm Step Motor 0.9 deg 1.8 Deg OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español