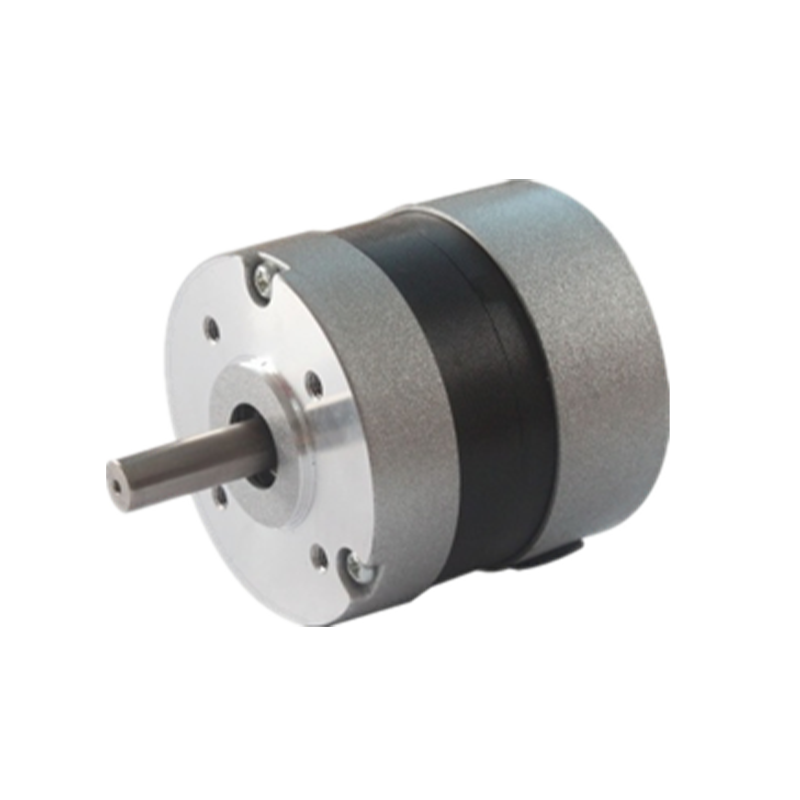

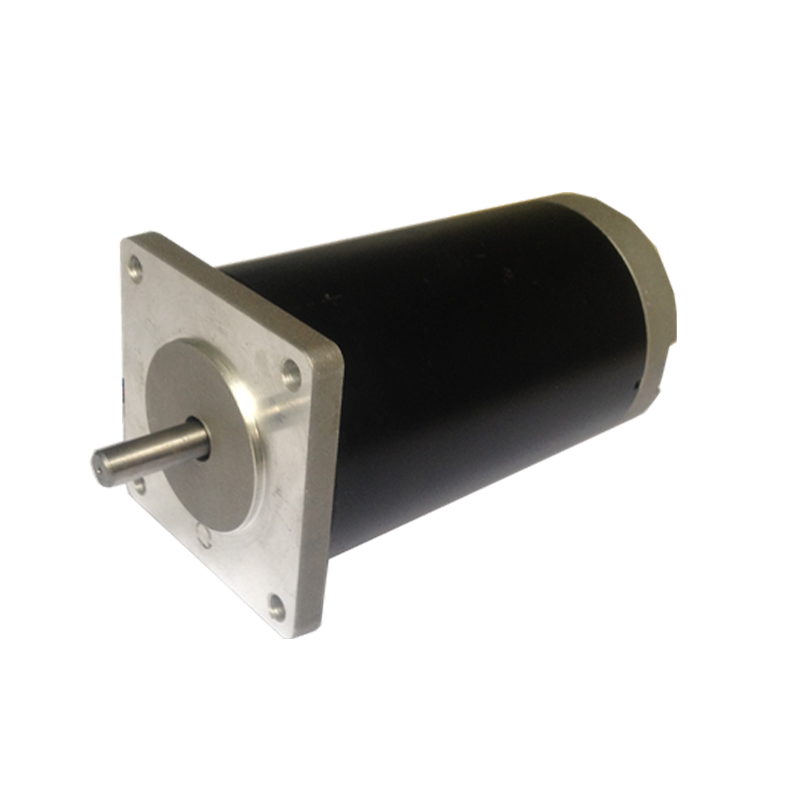

The NEMA 14 Stepper: Compact Precision Motion Control

The NEMA 14 stepper motor, with its 1.4 inch (approx. 35mm) square face, is a staple for compact, high-precision positioning systems.

This motor typically features a 1.8∘ step angle (200 steps per revolution) and operates in a bipolar configuration. The ST35 designation refers to a common standard motor length in this frame. The NEMA 14 is specifically engineered for a high holding torque relative to its small size, ensuring position maintenance even when power is removed or the motor is stationary. While smaller than NEMA 17, it is critical in applications where minimizing mass on moving axes (e.g., gantry systems) is paramount for achieving high acceleration.

Introduction

Detailed Parameters and Performance Data

RETEK: Positioning Accuracy in Miniature Automation

Suzhou Retek Electric Technology Co., Ltd. provides NEMA 14 stepper motors optimized for low-vibration and high-torque characteristics, essential for desktop CNC, 3D printing, and small laboratory equipment. Our manufacturing process minimizes stack height variation and ensures precise rotor-stator alignment, which translates directly to accurate step response and reduced positioning error in micro-motion systems. We focus on providing the highest holding torque within the NEMA 14 envelope.

Applications

Advanced Technology Highlights

Precision Applications for NEMA 14 Stepper Motors

- Desktop 3D Printers: Motors for X, Y, and Z axes where low mass is needed for fast printing speeds. Challenge: Minimizing resonance at micro-stepping frequencies.

- Small CNC Machines: Motors for the light-duty cutting and engraving axes.

- Optical Stage Positioning: Actuators for focusing mechanisms, aperture control, and small linear/rotary stages.

- Micro-Fluidics: Motors for peristaltic pumps and precise liquid dispensing.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters (NEMA 14 Stepper)

| Parameter | Range / Typical Value | Unit |

| Frame Size (NEMA) | 14 (35mm) | Standard |

| Step Angle | 1.8 | Degrees |

| Steps per Revolution | 200 | Steps |

| Holding Torque | Up to 0.25 | Nm |

| Current per Phase | 0.5 to 1.5 | A |

| Configuration | Bipolar (4-Lead) | Type |

Additional Information

Supplementary Details & Notes

Integrated Production and Customization Workflow

Our NEMA 14 production involves precise slot insulation and coil winding to minimize phase resistance variation, ensuring optimal micro-stepping performance. Each unit is tested for step angle accuracy.

- Custom Shaft Features: Integrating lead screw couplings, specialized gear pinions, or extending the shaft length for rear-mounted encoders (for closed-loop stepper systems).

- Holding Torque Tuning: Offering customized winding (higher current/lower voltage) to maximize holding torque for specific stationary applications.

- Acoustic Damping: Integrating vibration-dampening mounting pads or internal damping materials to reduce transmitted noise in 3D printers and quiet lab environments.

- IP Rating: Providing optional sealing of the terminal exit and front bearing for dusty or moist environments (e.g., light-duty industrial use).

About Jiangsu Retek Motion Co., Ltd.

As China Nema 14 Stepper Motor 3D Printer CNc High Torque 1.8 Deg Standard Step ST35 Stepping Motor Manufacturers and Wholesale Nema 14 Stepper Motor 3D Printer CNc High Torque 1.8 Deg Standard Step ST35 Stepping Motor OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español