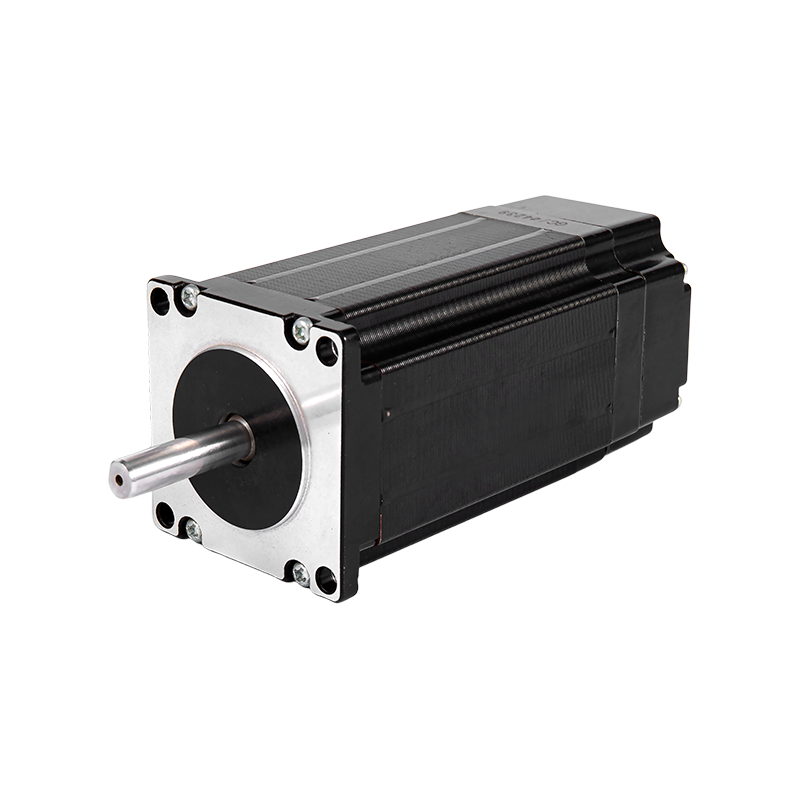

8-Wire NEMA 23 Stepper: Maximum Winding Flexibility

The 8-Wire NEMA 23 Stepper Motor is the most versatile configuration, featuring all four ends of the two independent motor windings brought out to the connection terminals.

This provides maximum flexibility for the user to configure the motor to achieve different performance characteristics: 1) Series Connection (Max Torque): Highest inductance, high resistance, highest torque at low speeds. 2) Parallel Connection (Max Speed): Lowest inductance, low resistance, best torque at high speeds. 3) Half-Coil (Uni-polar): Simplest drive, but lowest torque. The 8-wire motor allows system designers to precisely tune the motor's electrical time constant to match their application's speed/torque profile.

Introduction

Detailed Parameters and Performance Data

RETEK: Versatility for Performance Optimization

Suzhou Retek Electric Technology Co., Ltd. provides the 8-wire NEMA 23 series for engineers who need to extract every ounce of performance from their stepper system. We provide detailed data for all three wiring configurations, allowing the user to select the optimal setup for either maximizing acceleration (parallel) or maximizing static holding force (series).

Applications

Advanced Technology Highlights

Advanced Configuration Applications for 8-Wire Steppers

- CNC Routers and Mills: Motors where the X and Y axes might require high-speed (parallel) while the Z axis might require high holding torque (series). Challenge: Optimizing different axes on the same machine.

- Automated Assembly Lines: Drives for indexing tables where initial startup may be slow (high torque), but continuous operation is fast.

- Laser Engravers: Balancing high-resolution positioning (low speed) with fast travel moves (high speed).

- Custom Test Rigs: Systems where the required speed/torque changes depending on the test profile.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters (8-Wire NEMA 23)

| Parameter | Range / Typical Value | Unit |

| Frame Size | NEMA 23 (57mm) | Standard |

| Wire Count | 8 | Wires |

| Connection Options | Series, Parallel, Uni-polar | Configuration |

| Torque (Series) | Max Static Torque (Low Speed) | Feature |

| Torque (Parallel) | Max Dynamic Torque (High Speed) | Feature |

Additional Information

Supplementary Details & Notes

Production & Customization Services

Production includes individual testing of each of the four coil halves to ensure matched resistance and inductance, guaranteeing symmetrical performance in all connection modes.

- Custom Cable Length/Connector: Providing custom cable assemblies with the four connection pairs pre-terminated into multi-pin connectors (e.g., M12).

- Dual Shaft Option: Providing a rear shaft for encoder mounting, regardless of the front-end wiring configuration.

- High Vacuum Prep: Offering specialized versions with low-outgassing materials for clean-room or vacuum applications.

- Thermal Monitoring: Integration of an internal thermistor to allow the drive to manage current based on the winding temperature (especially critical in parallel mode).

About Jiangsu Retek Motion Co., Ltd.

As China High Torque Nema 23 Stepper Motor 8-Wire Bi-Polar/Uni-Polar Manufacturers and Wholesale High Torque Nema 23 Stepper Motor 8-Wire Bi-Polar/Uni-Polar OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español