Hollow Shaft NEMA 17 Stepper: Feed-Through Integration

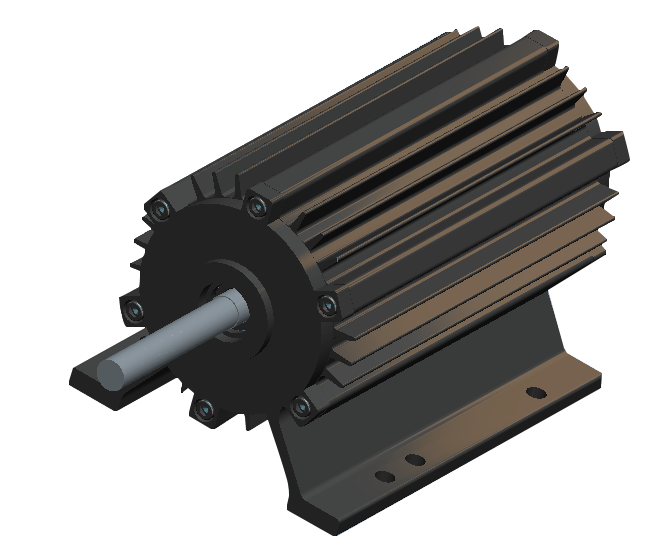

The Hollow Shaft NEMA 17 Stepper Motor (42mm frame) features a bore running entirely through the center of the motor rotor and shaft.

This unique design is essential for applications requiring the routing of cables, pneumatic lines, laser beams, or fluids through the rotation axis. Mechanically, the motor retains the high-precision indexing and holding torque characteristics of a standard NEMA 17 hybrid stepper. The integration of a hollow shaft eliminates the need for complex, bulky external cable management (like slip rings), simplifying machine design and improving reliability in rotary stages and actuators.

Introduction

Detailed Parameters and Performance Data

RETEK: Optimized for Direct Energy and Signal Routing

Suzhou Retek Electric Technology Co., Ltd. provides the hollow shaft series with guaranteed concentricity between the bore and the rotational axis. This precision is critical for maintaining step accuracy and minimizing vibration when cables or optical components are passed through. Our manufacturing process ensures that the internal routing channel is smooth and free of burrs, preventing cable abrasion during rotation. This specialty stepper is ideal for highly integrated, dynamic systems.

Applications

Advanced Technology Highlights

Unique Integration Applications for Hollow Shaft Steppers

- 3D Printing Extruder Heads: Routing filament, cooling tubes, or heating wires directly through the motor. Challenge: Minimizing drag and maximizing space utilization.

- Laser Welding/Cutting Heads: Passing the laser beam or welding gas supply directly through the rotation axis of a focus adjustment system.

- Fluidic Rotary Stages: Routing liquid or gas lines to a central dispenser or probe.

- Inspection Systems: Passing camera wiring or illumination fibers through the motor axis of a rotary inspection table.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters (Hollow Shaft NEMA 17)

| Parameter | Range / Typical Value | Unit |

| Frame Size (NEMA) | 17 (42mm) | Standard |

| Step Angle | 1.8 | Degrees |

| Hollow Bore Diameter | 4 to 8 | mm |

| Holding Torque (Typ.) | 0.3 to 0.8 | Nm |

| Thermal Management | Air Cooled/Passive | Type |

Additional Information

Supplementary Details & Notes

Integrated Production and Customization Workflow

Production includes a final concentricity check using precision jigs to verify that the bore axis aligns perfectly with the electrical axis of rotation, minimizing dynamic imbalance.

- Custom Bore Diameter: Adjusting the internal bore diameter (e.g., 6.35mm to 8mm) to match specific cable or fluid conduit sizes.

- Flange Modification: Customizing the mounting flange (NEMA standard or proprietary) to integrate a cable gland or sealing ring around the bore exit.

- Integrated Encoder/Potentiometer: Mounting a sensor to the hollow shaft output flange to track the absolute or incremental position of the rotating platform.

- Vacuum Compatibility: Customizing the motor (e.g., using low outgassing materials and eliminating standard lubricants) for use in vacuum environments.

About Jiangsu Retek Motion Co., Ltd.

As China Hollow Shaft Stepper Motor Nema 17 42mm Manufacturers and Wholesale Hollow Shaft Stepper Motor Nema 17 42mm OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español