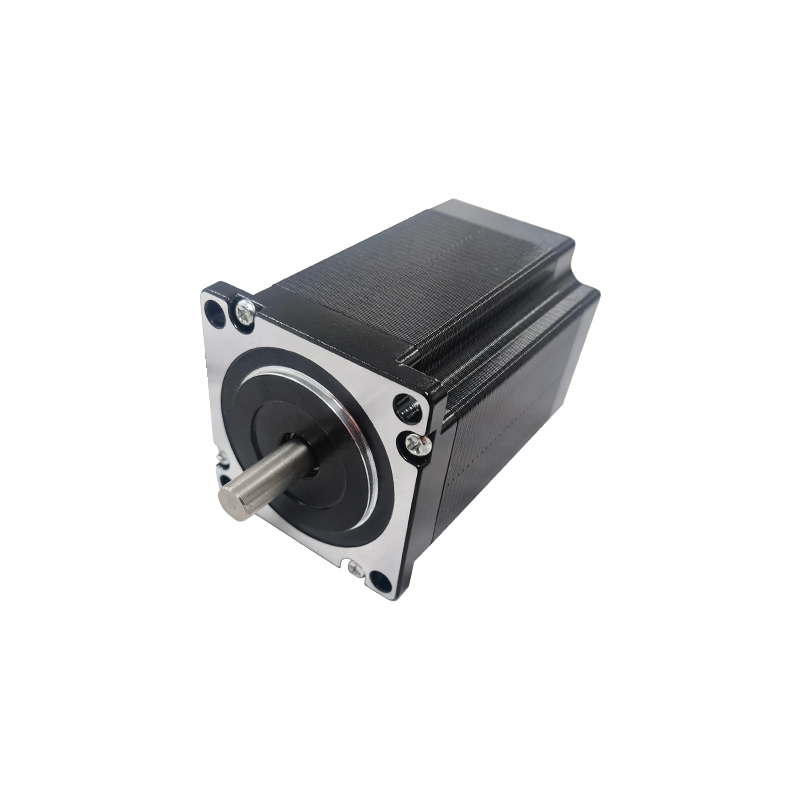

NEMA 17 Closed-Loop Stepper: Precision Without Stall Risk

The NEMA 17 Closed-Loop Stepper (often called a Servo-Stepper or Stepper-Servo) combines the high holding torque and low-speed accuracy of a standard stepper with the reliability and feedback of a servo system.

The key feature is the integration of a high-resolution encoder (1000 to 2500 lines per revolution) onto the motor's rear shaft. This encoder continuously monitors the rotor position. The specialized drive unit uses this feedback to actively manage the motor's phase current vector, ensuring it never misses a step, prevents stalling under high load, and minimizes step error. The 42mm frame provides a compact, high-precision alternative to micro-stepped open-loop systems or costlier low-power servos.

Introduction

Detailed Parameters and Performance Data

RETEK: Reliable Motion Control for Critical Processes

Suzhou Retek Electric Technology Co., Ltd. provides the Closed-Loop NEMA 17 solution for applications where positional integrity is crucial, such as medical dispensing and high-speed inspection systems. We integrate and pre-test the encoder and motor as a matched pair, guaranteeing commutation accuracy and positional repeatability. This system offers the best of both worlds: high holding torque at zero speed and dynamic error correction under acceleration/load.

Applications

Advanced Technology Highlights

High-Reliability Applications for Closed-Loop NEMA 17

- Medical Analyzers and Dispensers: Requiring absolute certainty that the commanded dose/position is achieved, crucial for sample handling. Challenge: Preventing stall and detecting unexpected physical obstruction.

- High-Speed 3D Printing and Laser Engraving: Systems where high acceleration is needed without losing steps, improving throughput and print quality.

- Automated Labeling and Inspection: Precise indexing and alignment of materials on a conveyor.

- Light-Duty Robotic Arms: Joints requiring high holding torque and position confirmation.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters (Closed-Loop NEMA 17)

| Parameter | Range / Typical Value | Unit |

| Frame Size (NEMA) | 17 (42mm) | Standard |

| Step Angle | 1.8 | Degrees (Native) |

| Encoder Resolution | 1000 to 2500 | PPR (Lines/Rev) |

| Operating Mode | Vector-Controlled Current Loop | Principle |

| Maximum Speed | Up to 2,000 | RPM |

Additional Information

Supplementary Details & Notes

Integrated Production and Customization Workflow

The production process includes a critical encoder alignment step where the zero pulse (Z-channel) is precisely aligned to the motor's full step position, ensuring optimal closed-loop performance from the first power-up.

- Matched Drive Systems: Offering the motor and drive unit as a tested, matched system with pre-tuned parameters for immediate use.

- Brake Integration: Providing optional power-off electromagnetic brakes, especially for vertical axes, integrated seamlessly with the rear encoder.

- Cable Harness: Customizing shielded, flexible cabling for both power (4-wire) and encoder signal (5-8 wires) for use in cable chains and dynamic environments.

- Environmental Protection: Enhancing sealing around the encoder and shaft to achieve specific IP ratings for dusty or damp operating conditions.

About Jiangsu Retek Motion Co., Ltd.

As China Closed Loop Stepper Motor Nema 17 42mm with Encoder Manufacturers and Wholesale Closed Loop Stepper Motor Nema 17 42mm with Encoder OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español