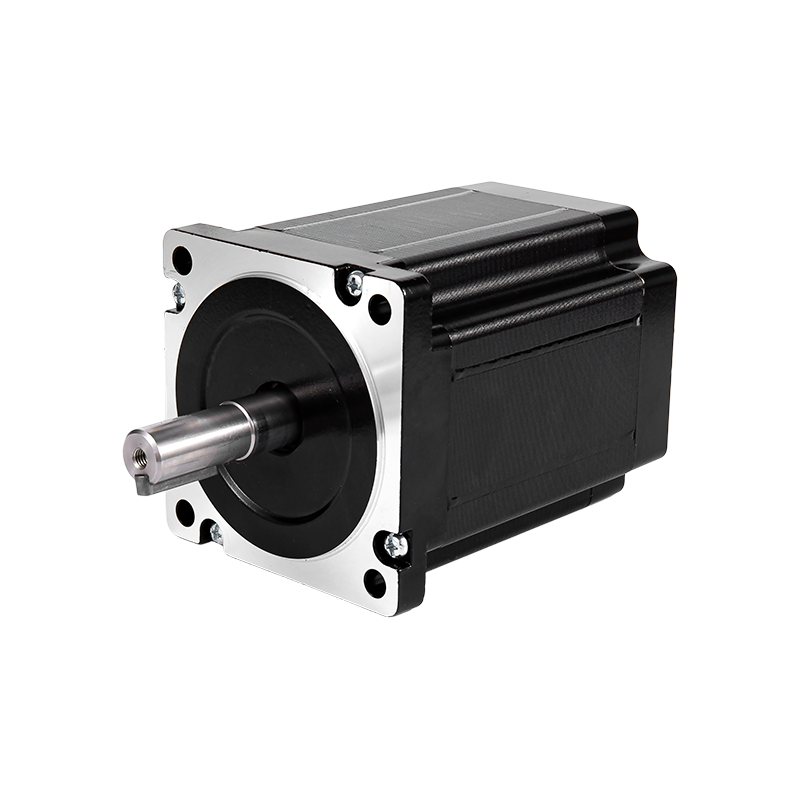

High-Resolution 0.9° Stepper: Doubling Positional Accuracy

The High Resolution Stepper Motor featuring a native 0.9∘ step angle (400 steps per revolution) offers twice the positional resolution of the standard 1.8∘ stepper (200 steps/rev).

This motor is critical for applications demanding extremely fine angular movement and enhanced micro-stepping performance. By doubling the number of physical steps, the motor reduces the static error between steps and provides smoother motion, especially important when operating at low micro-stepping resolutions (e.g., 1/2 or 1/4 step). The 0.9∘ motor typically has a slightly higher winding resistance/inductance than its 1.8∘ counterpart, which must be accounted for in the drive system design.

Introduction

Detailed Parameters and Performance Data

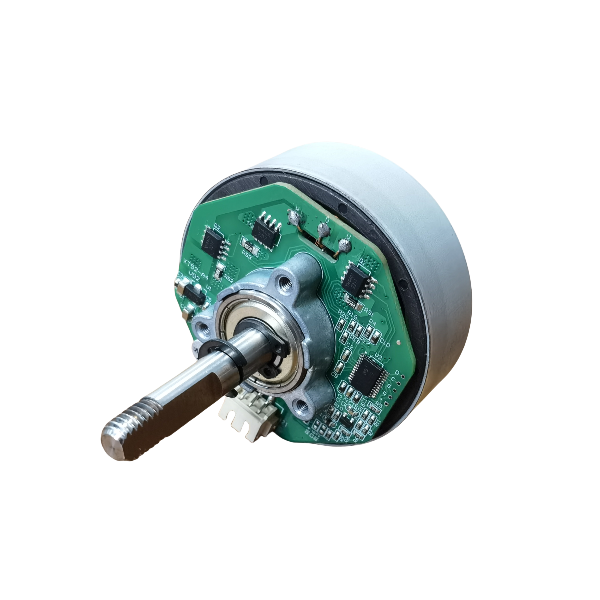

RETEK: Enhanced Precision for Optical and Alignment Systems

Suzhou Retek Electric Technology Co., Ltd. provides high-resolution steppers (0.9∘ and sometimes 0.45∘) for precision metrology, optical manipulation, and high-quality 3D printing. We focus on achieving the tightest possible step-angle tolerance (e.g., ±3%) through ultra-precision rotor-stator alignment and meticulous tooth geometry. This series offers superior positional accuracy and reduced vibration without the cost and complexity of a closed-loop servo system.

Applications

Advanced Technology Highlights

Extreme Precision Applications for 0.9° Stepper Motors

- Automated Optical Inspection (AOI) Systems: Motors for lens positioning, aperture control, and rotary stages requiring high angular fidelity. Challenge: Minimizing oscillation and maximizing repeatability.

- Scientific Instrumentation: Drives for spectrometers, laboratory fluidics, and high-precision sampling systems.

- High-Fidelity 3D Printers: Providing smoother Z-axis lift and more accurate X/Y movement, minimizing visible layer lines and artifacts.

- Micro-Machining: Actuators for small, high-precision linear and rotary stages used in micro-manufacturing.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters (0.9° High Resolution)

| Parameter | Range / Typical Value | Unit |

| Step Angle (Native) | 0.9 | Degrees |

| Steps per Revolution | 400 | Steps |

| Step Angle Tolerance | Typically ±3% | Percentage |

| Holding Torque Options | NEMA 17, 23, 34 | Frame Sizes |

| Micro-stepping Resolution | Up to 51,200 steps/rev | Achievable |

Additional Information

Supplementary Details & Notes

Integrated Production and Customization Workflow

Production includes advanced automated winding and final inspection via a dedicated step-angle testing system (torquemeter) to guarantee the advertised ±3% angular tolerance.

- Custom Winding Optimization: Providing customized windings to minimize inductance for the best balance of torque and speed in 0.9∘ models.

- Integrated Lead Screw: Factory assembly of the 0.9∘ motor with a precision rolled or ground lead screw for highly accurate linear motion applications.

- Vacuum/Cryogenic Use: Customizing materials and assembly procedures (e.g., low-outgassing grease, specialized wire insulation) for use in vacuum chambers or cryogenic environments.

- Integrated Damper: Providing factory-installed viscous dampers to further reduce low-speed resonance and improve settling time.

About Jiangsu Retek Motion Co., Ltd.

As China High Resolution Stepper Motor 0.9 Degree Step Manufacturers and Wholesale High Resolution Stepper Motor 0.9 Degree Step OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español