Micro Stepper Motors: Actuation in Confined Spaces

Micro Stepper Motors (diameters 8mm to 15mm) are miniature permanent magnet (PM) stepper motors designed for precision positioning in extremely space-constrained environments.

These motors feature high pole counts for their size and provide discrete, accurate angular movement suitable for delicate mechanisms. Due to their small size, they generally have low holding torque and low inertia, making them highly responsive. They are the ideal choice for driving gears, lead screws, or pinions in micro-actuation systems found in consumer electronics, medical diagnostics, and small format printers. They are typically driven by unipolar or bipolar low-voltage (3V to 5V) pulses.

Introduction

Detailed Parameters and Performance Data

RETEK: Miniaturized Positioning Solutions

Suzhou Retek Electric Technology Co., Ltd. specializes in the high-volume manufacturing of micro stepper motors with tight dimensional tolerances. We ensure the stability of the small magnet and rotor assembly, which is crucial for achieving repeatable micro-stepping in miniature systems. This series offers simple, cost-effective digital positioning control where brushed motors or miniature servos are too large or too complex to integrate.

Applications

Advanced Technology Highlights

Miniature and Highly Integrated Applications for Micro Steppers

- Camera Autofocus and Zoom: Motors for precise adjustment of optical lenses in smartphones, security cameras, and SLR lenses. Challenge: Small size, high precision, and low noise.

- Medical Micro-Pumps and Fluidics: Drives for miniature peristaltic pumps, micro-valves, and automated fluid dispensing.

- Automotive Gauge Clusters: Actuators for pointer needles in instrument panels.

- Credit Card/Bill Readers: Motors for precisely feeding or scanning paper currency and cards.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters (Micro Stepper Motors)

| Parameter | Range / Typical Value | Unit |

| Diameter | 8 to 15 | mm |

| Step Angle Options | 7.5, 15, or 18 | Degrees |

| Holding Torque | $ < 50$ | g ⋅ cm |

| Input Voltage | 3 to 5 | VDC |

| Drive Type | Permanent Magnet (PM) | Design |

Additional Information

Supplementary Details & Notes

Integrated Production and Customization Workflow

Production involves high-speed automated coil winding and precise terminal welding. The motor's phase resistance and step torque are tested via automated optical inspection systems.

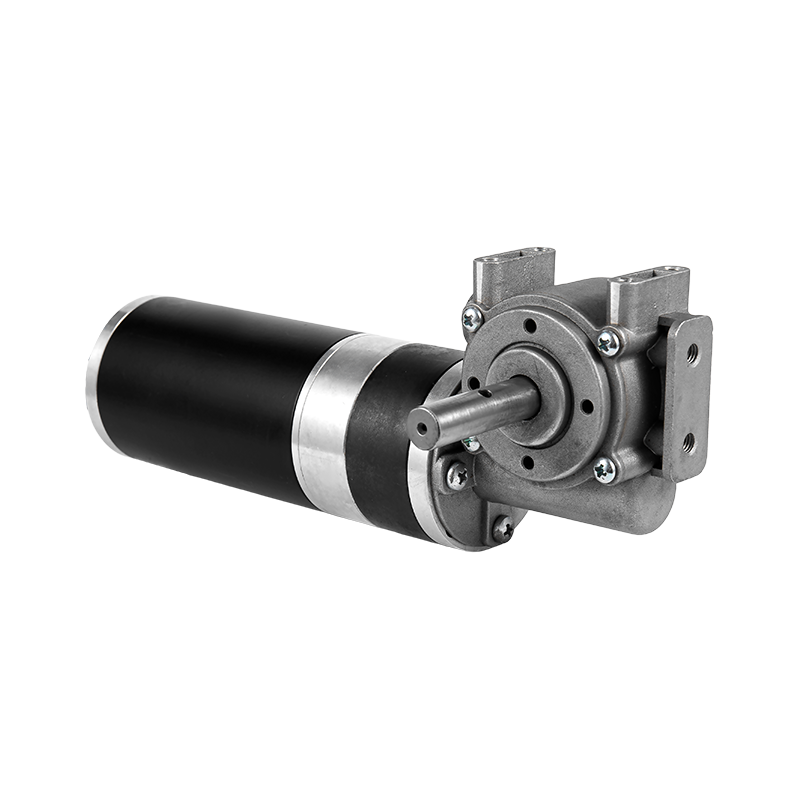

- Custom Pinion Integration: Factory mounting of specific-module pinions (e.g., 0.5M or 0.3M) directly onto the shaft for immediate gearbox integration.

- Integrated Gearbox: Providing the motor and a miniature multi-stage spur gear reduction unit as a fully assembled, lubricated module.

- Connector Harness: Providing ultra-fine wire cable harness with miniature connectors (e.g., JST SH/GH) to client-specified length.

- Vibration Dampening: Custom mounting interfaces or pads designed to absorb the motor's vibration for noise-sensitive products.

About Jiangsu Retek Motion Co., Ltd.

As China Micro Stepper Motor 8mm 10mm 15mm Small Stepping Motor Manufacturers and Wholesale Micro Stepper Motor 8mm 10mm 15mm Small Stepping Motor OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español