Coreless DC Motor: High Efficiency, Dynamic Response, and Miniaturization

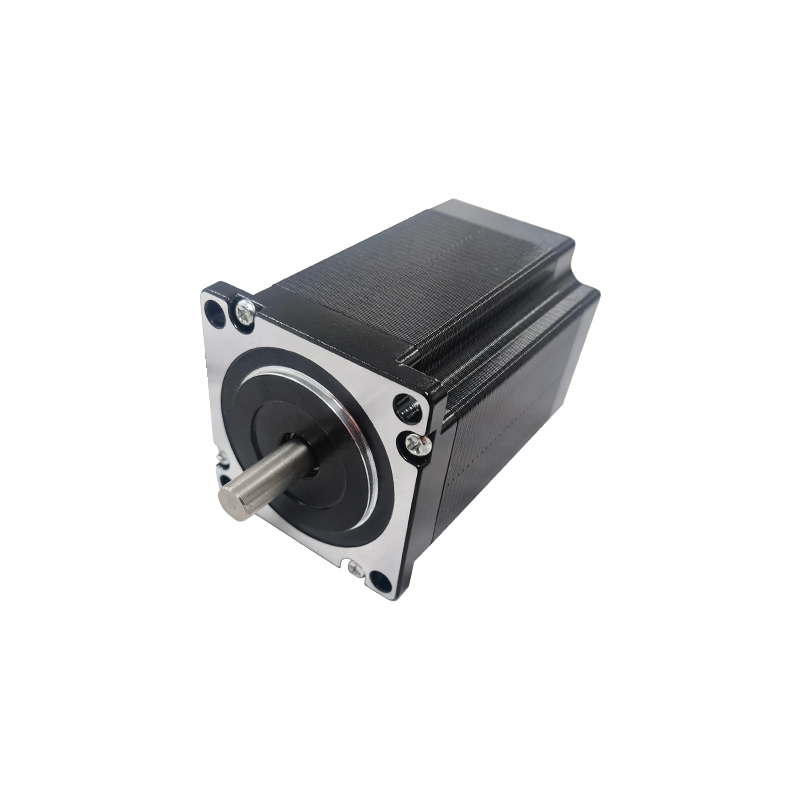

The Coreless Brushed DC Motor (diameter 10mm to 20mm) is a specialized permanent magnet motor design where the rotor winding is a self-supporting, basket-like cup (skew-wound) without a ferrous core.

The absence of an iron core results in three major technical advantages: 1) Extremely Low Rotor Inertia: Leading to phenomenal acceleration, deceleration, and high dynamic response (short mechanical time constant). 2) Zero Cogging Torque: The lack of slotting means the motor rotates smoothly, even at very low speeds. 3) High Efficiency: Minimal core losses. These characteristics make them indispensable for portable, precision, and high-response micro-actuators, often operating on low voltage (e.g., 3V to 12V).

Introduction

Detailed Parameters and Performance Data

RETEK: Micromotion and Portable Power Precision

Suzhou Retek Electric Technology Co., Ltd. provides high-precision coreless motors for applications where size, weight, efficiency, and dynamic performance are paramount. We use precious metal commutation systems (gold/silver alloy) in the smallest sizes to ensure low electrical noise and high starting reliability. Our production focuses on precise winding symmetry and dynamic balancing to maximize the motor's lifespan and efficiency under high-speed operation, typically in conjunction with miniature gearheads.

Applications

Advanced Technology Highlights

Precision and Portable Applications for Coreless DC Motors

- Miniature Robotics and Drones: Actuators for micro-flaps, gimbals, and small flight control surfaces requiring extremely fast response. Challenge: High power-to-weight ratio.

- Medical Handheld Devices: Motors for surgical tools, drug dispensing pumps, and portable diagnostic equipment.

- Optical Focus and Zoom: Actuators for automated lenses and micro-positioning stages requiring sub-micron resolution control.

- Tattoo Pens and Power Tools: Lightweight motors requiring high speed and smooth operation.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters (Coreless Brushed DC)

| Parameter | Range / Typical Value | Unit |

| Diameter | 10 to 20 | mm |

| Rotor Inertia | Extremely Low | g ⋅ cm$^2$ |

| No-Load Speed | 5,000 to 15,000 | RPM |

| Commutation | Precious Metal or Carbon | Type |

| Mechanical Time Constant | Typically <10 | ms |

Additional Information

Supplementary Details & Notes

Integrated Production and Customization Workflow

Manufacturing involves automated coil winding and precise balancing of the rotor cup. Final testing includes measuring the mechanical time constant and ensuring the no-load current is minimal, indicating high efficiency.

- Miniature Gearhead Coupling: Factory integration with low-backlash miniature planetary gearheads (e.g., 16mm or 22mm) for high-torque output.

- Integrated Encoder/Tachometer: Mounting miniature magnetic or optical encoders to the motor's rear shaft for closed-loop speed and position control.

- Winding Optimization: Customizing the winding to meet specific battery voltages (e.g., 3.7V, 7.2V) for optimal efficiency in portable devices.

- Shaft Customization: Providing custom shaft lengths, micro-splines, or pinions for direct integration into client assemblies.

About Jiangsu Retek Motion Co., Ltd.

As China Coreless Brushed Dc Motor 10mm to 20mm High Efficiency Manufacturers and Wholesale Coreless Brushed Dc Motor 10mm to 20mm High Efficiency OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español