Optimizing Power Delivery in the 24VDC Safety Standard

The 24VDC standard is prevalent due to its classification as Safety Extra Low Voltage (SELV) and its compatibility with battery systems.

The challenge in the 24VDC domain is efficiently handling high current. Our motor design addresses this by employing windings with extremely low resistance (milliohms), requiring thicker copper wire and high-precision coil placement to maximize the cross-sectional area. The magnetic circuit is highly saturated to produce maximum torque from the limited voltage. For high-power 24V applications (e.g., 3kW axial fan motors), the driver and motor are engineered as a single thermal unit to manage the significant I2R heat loss, which is inherently higher at low voltage and high current.

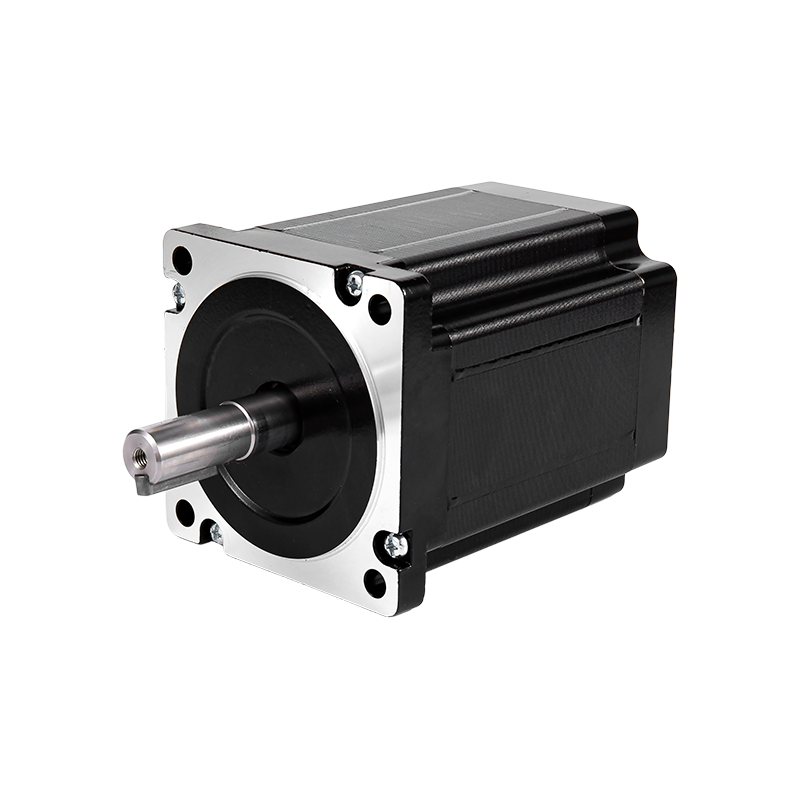

The BL112 Low Cogging Effect series highlights an optimization for smooth, low-speed maneuvers typical in battery-powered automation.

Introduction

Detailed Parameters and Performance Data

RETEK: The 24VDC Industrial Power Platform Specialist

Suzhou Retek Electric Technology Co., Ltd. provides robust, high-current management solutions within the 24VDC framework, serving crucial logistics, mobile machinery, and renewable energy storage applications. Our motors are rigorously tested for performance over the typical 20V to 30V range expected from charging/discharging batteries. We focus on maximizing run-time and minimizing energy consumption by achieving peak efficiencies that reduce the load on the power source, extending the operational period of electric forklifts (BL100 series) and industrial pump systems.

Applications

Advanced Technology Highlights

24VDC Specific Application Environments

- Electric Forklifts and Pallet Jacks: Drive and lift motors requiring high transient torque for starting under load and efficient cruising (e.g., BL100, 300W series). Challenge: High shock and vibration immunity.

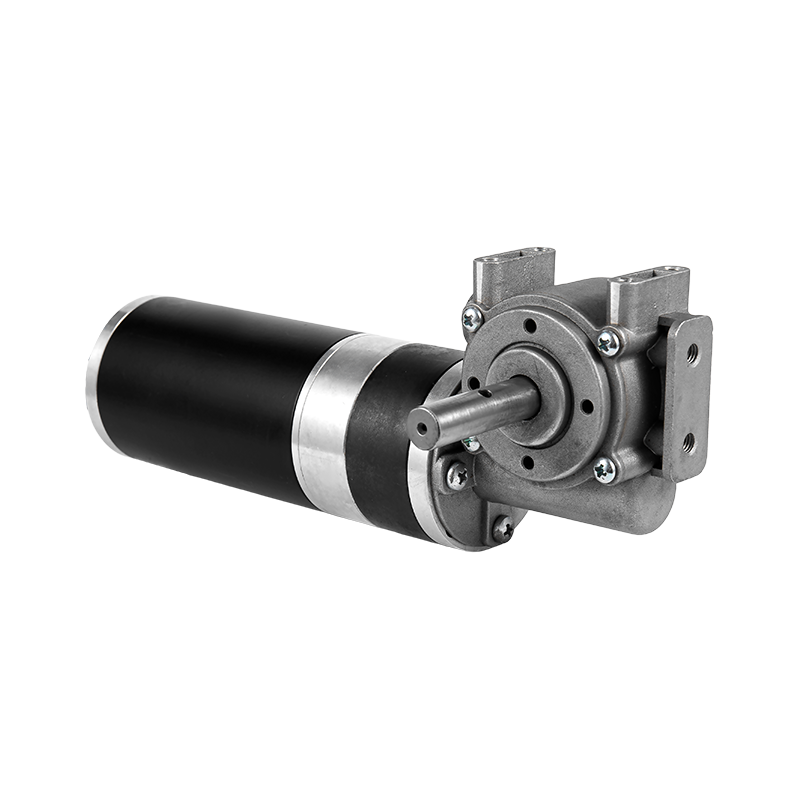

- Water and Submersible Pumps: DC pumps for wells, pools, or marine applications running directly off batteries or solar panels. Challenge: Requires exceptional sealing (IP68) and corrosion-resistant materials.

- Mobile Autonomous Systems: The primary drive train for AGVs and large wheeled service robots. Challenge: Must handle regenerative braking energy back into the battery safely.

- Industrial Axial Fans (High Power): Low voltage, high power (e.g., 3kW) fans for ventilation in mines or large industrial enclosures where safety standards prohibit high voltage.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters

| Parameter | Range / Typical Value | Unit |

| Nominal Input Voltage | 24 | VDC |

| Winding Resistance (Rw) | <50 | m Ω |

| Torque Constant (KT) | High, KV Low | Nm/A |

| Low Cogging Effect Series | <2% of Rated Torque | Ripple |

| Insulation Class | F (Standard) | Rating |

| Max Operating Current | Up to 150 | A |

Additional Information

Supplementary Details & Notes

Integrated Production and Customization Workflow

Our production process includes mandatory high-current life cycle testing to validate thermal stability under maximum load. We ensure all terminal connections are ultrasonically welded or crimped with industrial-grade tooling to prevent high-resistance contacts at high currents.

- Custom Winding: Offering precise winding adjustments to tailor the KV curve for specific battery voltage ranges (e.g., 24V nominal but optimized for 22V minimum).

- IP Rating and Coating: Providing specialized conformal coatings for electronics and sealed cable entry points for motors used in environments with condensation or water exposure.

- Interface Standardization: Customizing the mounting flange and shaft dimensions (e.g., keyway, spline) to directly interface with common industrial gearboxes and coupling types.

- Encoder Integration: Integrating robust, industrial-grade incremental or absolute encoders with high signal noise immunity for reliable position feedback in noisy 24V systems.

About Jiangsu Retek Motion Co., Ltd.

As China Low Voltage Brushless DC Motors (24VDC) Manufacturers and Wholesale Low Voltage Brushless DC Motors (24VDC) OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español