Structural Engineering for Kilowatt Continuous Output

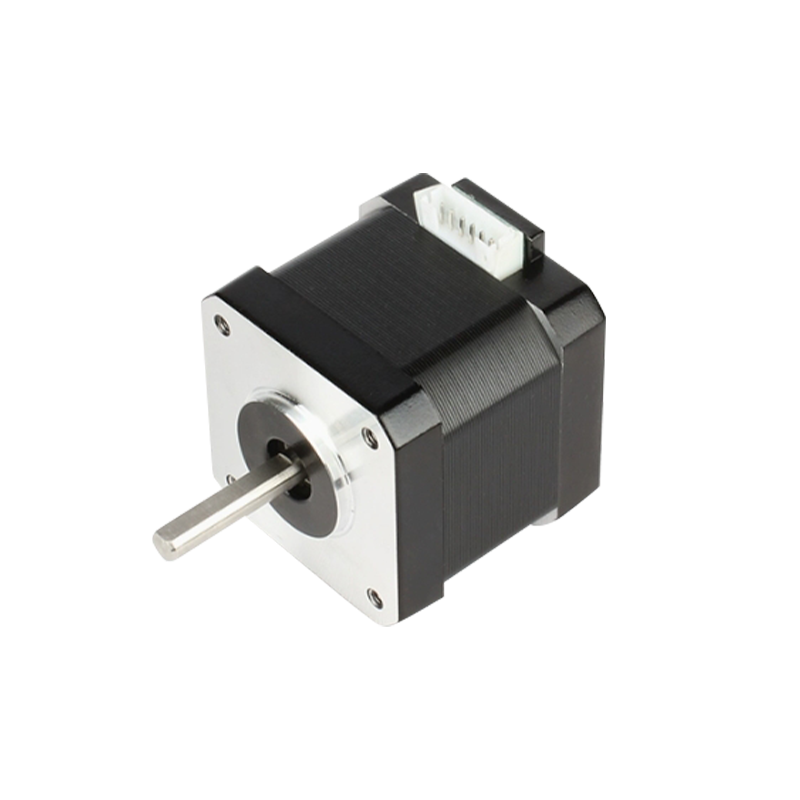

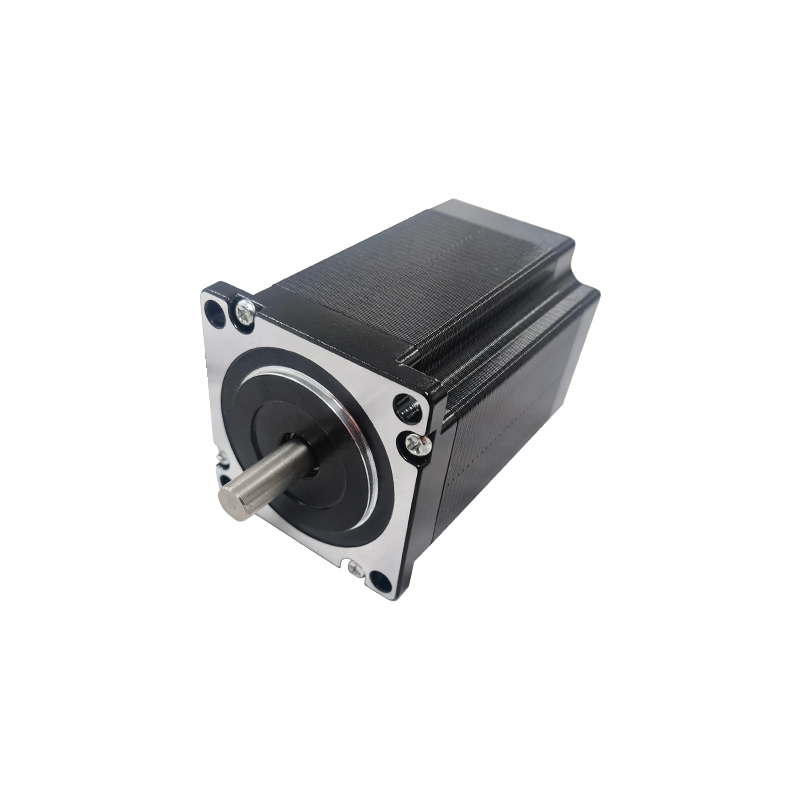

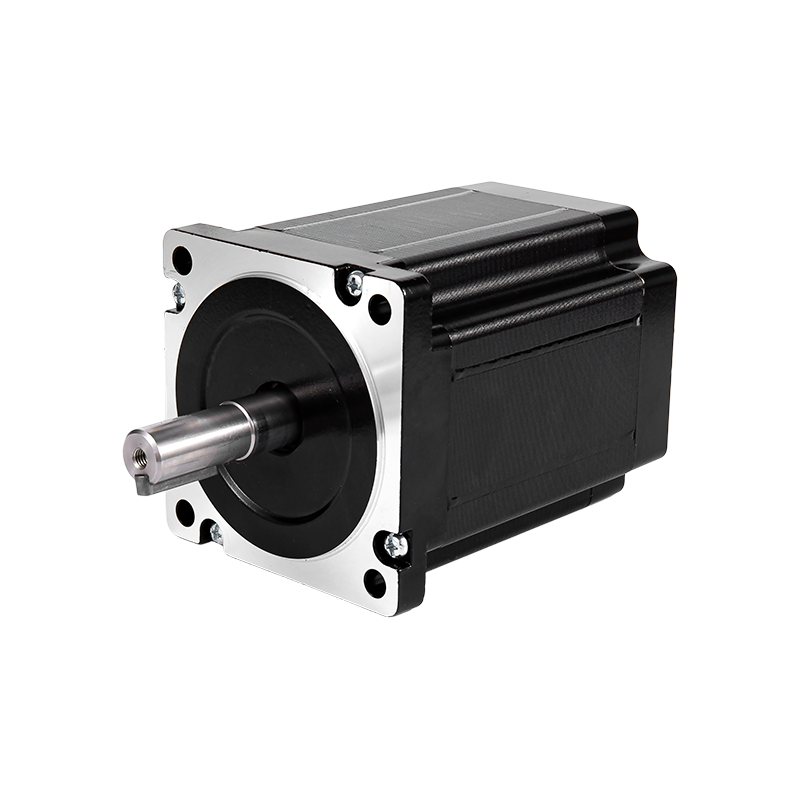

High power BLDC motors are designed to operate continuously at outputs greater than 1kW, challenging the thermal and mechanical limits of standard motors. They often feature an elongated, square, or large-diameter cylindrical frame (e.g., BL130 series, 86mm square CNC motor).

The key is efficient heat removal. This is achieved through large surface area heat sinks, internal flow channels for forced air (e.g., CNC Spindle motor with air cooling), or liquid cooling jackets. Electrically, these motors are optimized for higher voltage (310VDC or 230VAC) to reduce the current (I=P/V) and therefore minimize I2R losses, improving overall efficiency to 90% or greater. The rotors are typically inertia-optimized to handle the high speeds often associated with high power applications (e.g., blowers and spindles) while maintaining mechanical integrity at high centrifugal forces.

Introduction

Detailed Parameters and Performance Data

RETEK: Building Reliability for Heavy Industry and Automation

Suzhou Retek Electric Technology Co., Ltd. serves the high-end industrial power market, where motor sizing and thermal management are paramount. Our high-power motors (e.g., 2kW, 3.5kW) are engineered to deliver high dynamic performance comparable to traditional AC servo motors but with the superior efficiency of BLDC technology. We provide comprehensive thermal analysis and mechanical FEA reports for our industrial clients, guaranteeing performance under continuous rated load. The BL86mm Square Motor 310VDC is a solution for compact yet powerful drives in industrial automation.

Applications

Advanced Technology Highlights

High Power, High Duty Cycle Application Environments

- Industrial Ventilation and Air Movement: Large-scale heavy-duty blower motors (e.g., BL130 2kW) for drying, filtering, and climate control in factories and data centers. Challenge: High acoustic output and continuous operation at varying speeds.

- High-Speed Machining Spindles: Motors for milling and engraving (e.g., 3.5kW CNC spindle motor) requiring extremely smooth high-speed rotation and high power density. Challenge: Precise speed control across a wide RPM range and effective removal of internal heat.

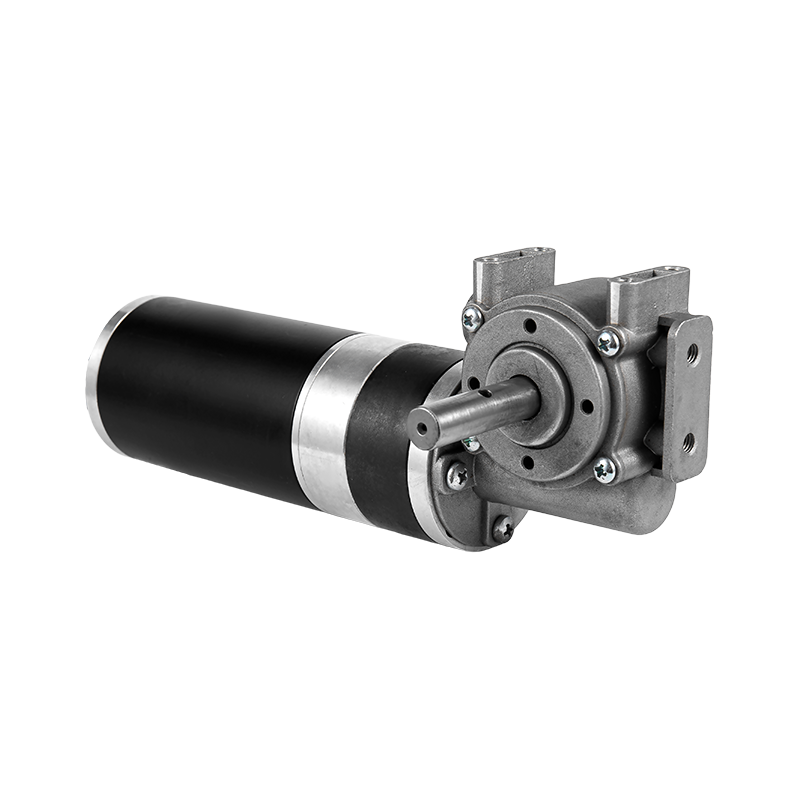

- Electric Vehicle Traction: Motors for industrial vehicles (e.g., airport tugs, large AGVs) or high-performance golf carts requiring sustained high torque and power for acceleration.

- Industrial Pump and Compressor Drives: Motors for large compressors, high-pressure washers, and hydraulic pumps.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters

| Parameter | Range / Typical Value | Unit |

| Rated Continuous Power | 1 to 5+ | kW |

| Operating Voltage (DC Bus) | 170 VDC to 310 VDC | V |

| Peak Current Density | Optimized Low | A/mm$^2$ |

| Efficiency (Maximum) | > 90 | % |

| Rotor Balancing Grade | G2.5 or better | Standard |

| Cooling Method Options | Passive/Forced Air/Liquid Cooled | Type |

Additional Information

Supplementary Details & Notes

Integrated Production and Customization Workflow

Production for high-power motors emphasizes robust mechanical assembly, including hydraulic pressing of components and precision interference fits to manage large thermal expansion/contraction cycles. Final QC involves high-voltage insulation tests (Hi-Pot) and full load dynamometer testing.

- Cooling Interface Design: Customization of the cooling manifold (inlet/outlet port locations) for integration with client-specific thermal management systems (e.g., specific fluid couplings).

- Integrated Sensors: Custom fitting of temperature sensors (PT1000 or NTC thermistors) directly into the winding end-turns for superior thermal monitoring and protection via the external drive.

- Custom Shaft Extensions: Providing double-ended shafts, specialized splines, or threaded features for direct connection to pump impellers or gearboxes.

- High-Speed Balancing: Individual balancing of rotors to meet the specific G-grade requirement for the maximum operating speed of the application.

About Jiangsu Retek Motion Co., Ltd.

As China High Power Brushless DC Motors Manufacturers and Wholesale High Power Brushless DC Motors OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español