Design Innovation in Miniaturized Coreless and Cored BLDC Technology

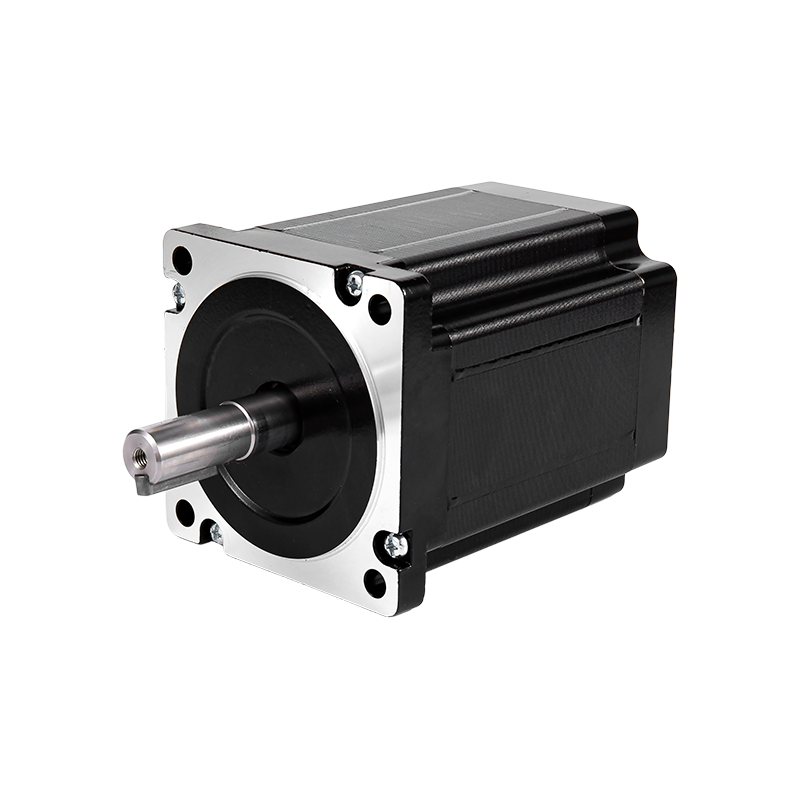

Compact BLDC motors are fundamentally driven by the need for high efficiency and dynamic performance within extremely confined spaces. Our range includes Coreless BLDC motors (e.g., WC 22 Series) and miniaturized cored motors.

Coreless designs eliminate iron losses (hysteresis and eddy currents) and cogging torque, resulting in smoother operation, especially at low speeds, and a significantly lower rotor inertia. This is vital for quick start/stop cycles, such as in medical dispensing or handheld fan motor applications (Wo22 Series, 20000RPM). Cored designs, though heavier, achieve higher torque density via very thin stators (<0.2mm) and high slot fill factors.

The key technical challenge is heat management; our motors address this with specialized housing materials and potting compounds that improve heat conduction from the winding to the motor casing.

Introduction

Detailed Parameters and Performance Data

RETEK: Precision and Reliability in Micro-Motion Control

Suzhou Retek Electric Technology Co., Ltd. excels in the sub-50mm diameter motor category, demanding micron-level precision in assembly. We serve demanding sectors like surgical robotics and high-end personal devices where minimal weight and acoustic output are non-negotiable. Our engineering team focuses on creating a high KV (speed constant) with a low mechanical time constant, facilitating rapid control loops and instantaneous response. The compact servo motors for medical use are manufactured in a controlled environment to ensure the highest standards of cleanliness and consistency required by medical device OEMs.

Applications

Advanced Technology Highlights

Micro-Applications and Constraints

- Surgical Robotics and Medical Drills: Motors for minimally invasive surgical tools and high-speed dental drills. Constraint: Must be sterilizable (autoclavable) or disposable, and generate minimal vibration/heat.

- High-Speed Personal Fans/Blowers: High KV motors (up to 40,000 RPM) for high-performance handheld fans and small vacuum cleaners. Constraint: Acoustic noise must be strictly controlled, necessitating dynamic balancing to G1.0 or better.

- Ai Camera and Lidar Systems: Motors for auto-focus mechanisms, gimbal stabilization, and shutter control. Constraint: Zero backlash and instantaneous settling time for optical precision.

- Micro Actuators: Motors in prosthetic devices, miniature grippers, and laboratory pipetting systems.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters

| Parameter | Range / Typical Value | Unit |

| Outer Diameter Range | 15 to 30 | mm |

| Mechanical Time Constant (τm) | < 10 | ms |

| Nominal Voltage | 3.7 to 24 | VDC |

| Acoustic Noise (No Load) | < 40 | dBA |

| Rotor Inertia (J) | Extremely Low | g ⋅ cm$^2$ |

| Protection Options | IP50 to IP65 | Rating |

Additional Information

Supplementary Details & Notes

Integrated Production and Customization Workflow

Our assembly utilizes automated dispensing equipment for precise adhesive application and uses laser welding for critical terminal connections to ensure reliability. Every motor undergoes a high-speed break-in and acoustic signature test before shipment.

- Shaft Material and Hardness: Customizing the shaft material, heat treatment, and surface finish (e.g., passivation) based on the client's output mechanism (e.g., gear, pulley, spline).

- Acoustic and Vibration Tuning: Specific adjustments to the dynamic balancing and bearing choice to meet client-specific noise floor requirements (e.g., for quiet environments).

- Sterilization Compatibility: Using autoclavable materials (e.g., PEEK, specific magnet coatings) for medical devices that require steam sterilization.

- Integrated Driver PCB: Designing and integrating the micro-driver PCB directly into the motor endcap to achieve the ultimate compact system form factor.

About Jiangsu Retek Motion Co., Ltd.

As China Compact DC Brushless Motors Manufacturers and Wholesale Compact DC Brushless Motors OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español