Low Cogging BLDC Motor Design Principle

The principle of low cogging involves minimizing the reluctance variation between the rotor magnets and the stator teeth as the motor rotates. This essential reduction is achieved through several design techniques: non-slotted stator structures (slotless design for zero cogging), skewed stator laminations (to average out the cogging peaks), and specific slot/pole count ratios (e.g., fractional slot windings) which inherently reduce ripple. The result is a substantial decrease in static torque ripple, often to less than 1% of the motor's rated torque, leading to smoother, more stable motion and a significant reduction in acoustic noise generation. This characteristic is essential for precision positioning, constant velocity control, and acoustic-sensitive applications.

- Focus Area: Smooth motion profile, high positional accuracy, and minimal acoustic signature.

- Key Technology: Precision magnet segmentation, skewed magnet or stator stacks, and advanced magnetic simulation to optimize geometries.

- Benefit: Improves control loop stability, eliminates low-speed jitter, and enhances positional accuracy, particularly at slow speeds.

- Comparison: Cogging torque is typically 10-20 times lower than in a standard, un-skewed iron-core motor.

Introduction

Detailed Parameters and Performance Data

Introduction to Smooth Motion Control Solutions

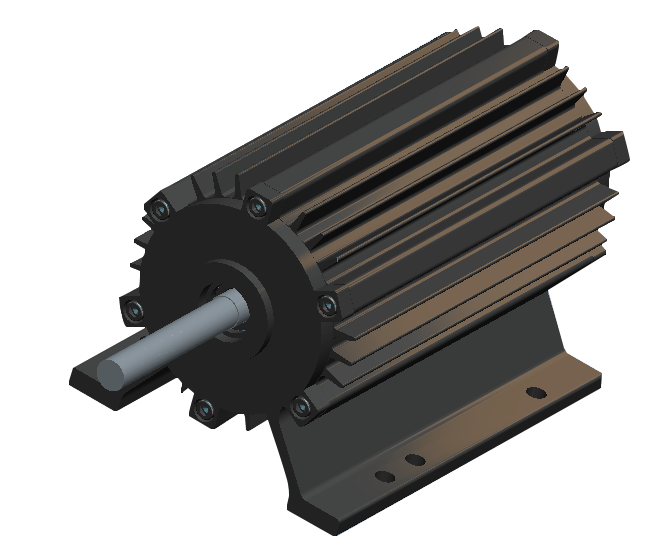

In applications where fine control, high resolution, and minimal vibration are paramount—such as in medical imaging or high-end laboratory equipment—standard iron-core motors often introduce limitations due to inherent cogging torque. This series of low cogging motors from Retek Electric Technology (RTK) is specifically designed to overcome this challenge. We leverage advanced Finite Element Analysis (FEA) modeling and precision assembly techniques to virtually eliminate static torque ripple. Our commitment as a dedicated motor manufacturer is to enable clients in sectors like medical robotics, optical systems, and high-fidelity printing to achieve uncompromising smoothness and repeatability in their motion systems, fulfilling the need for precision actuation at any speed.

Applications

Advanced Technology Highlights

Key Application Areas

- Medical Diagnostics & Surgery: High-precision fluid delivery (infusion pumps), diagnostic imaging gantry positioning, and minimally invasive surgical robotics requiring smooth, backlash-free movement.

- Optical & Scientific Equipment: Focusing mechanisms, mirror positioning, laser beam steering, and high-resolution microscopy stages.

- Semiconductor Manufacturing: Wafer handling and precise stage positioning where any vibration could compromise process integrity.

- Laboratory Automation: High-throughput sample handling systems, precision pipetting robots, and micro-dosing pumps requiring consistent, low-speed flow.

- High-End Printing & Plotting: Precision paper/media feeding and printhead positioning requiring constant velocity and zero jitter.

- Security and Surveillance: Silent, high-resolution Pan/Tilt/Zoom (PTZ) systems for discreet operation.

Technical Specifications

Industrial & Commercial Usage

Selected Motor Specifications

Low cogging motors are often compact but designed for high sensitivity.

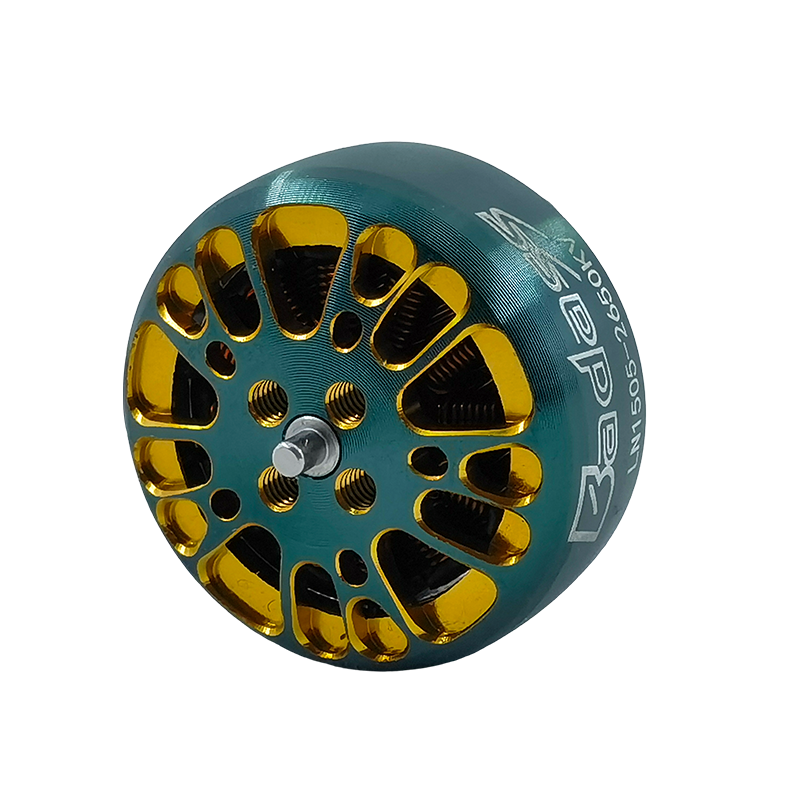

| Parameter | Example WC22 Coreless Series (Micro Low Cogging) | Example WO42 Outrunner Series (Skewed) |

| Peak Torque (Nm) | 0.08 - 0.15 | 0.35 - 0.50 |

| Cogging Torque (Max mNm) | <0.05 (Near Zero) | <1.5 (Low Ripple) |

| Rated Voltage (VDC) | 12 / 24 | 24 / 48 |

| Motor Diameter (mm) | 22 | 42 |

| Nominal Speed (RPM) | 500−8,000 | 500−5,000 |

| Positional Accuracy (Open Loop) | N/A (Requires Encoder) | ±0.5 mechanical degrees |

Additional Information

Supplementary Details & Notes

Manufacturing Process and Customization Services

Our low cogging motor production involves specialized processes to maintain geometric precision and magnetic symmetry:

- Precision Skewing/Coreless Winding: Utilizing high-accuracy indexing tables and automated laser alignment to ensure the precise angle of the skew or the perfect consistency of the coreless winding structure.

- High-Resolution Dynamic Balancing: Every low cogging motor is subjected to G-level dynamic balancing (e.g., G1.0) to eliminate vibration at high speeds, complementing the static smooth-motion design.

- Magnetic Field Mapping: Non-contact measurement systems are used to map the magnetic field symmetry around the rotor to detect and correct any flux inconsistencies.

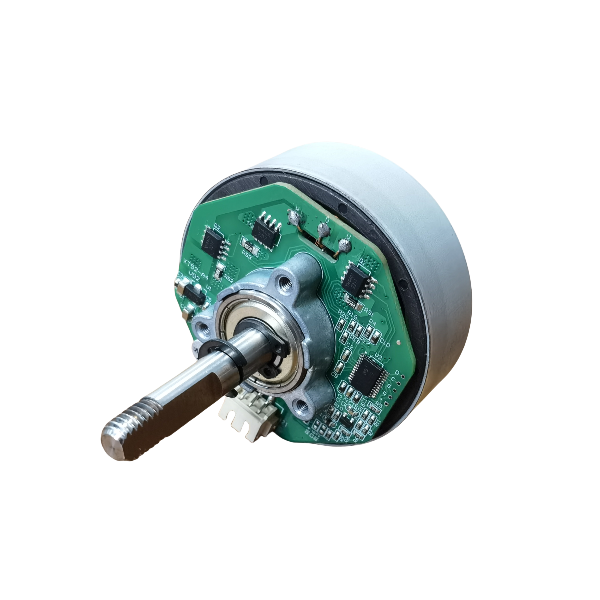

- Integrated Sensor Options: Offering high-resolution absolute or incremental encoders, including Sin/Cos encoders, to provide feedback resolution that matches the motor's motion smoothness.

- Controlled Environment Assembly: Motors intended for ultra-precision use are assembled in clean environments to prevent contamination that could introduce imbalance or noise.

About Jiangsu Retek Motion Co., Ltd.

As China Low Cogging Brushless DC Motors Manufacturers and Wholesale Low Cogging Brushless DC Motors OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español