Iron Core BLDC Linear Motor: Extreme Continuous Force Density

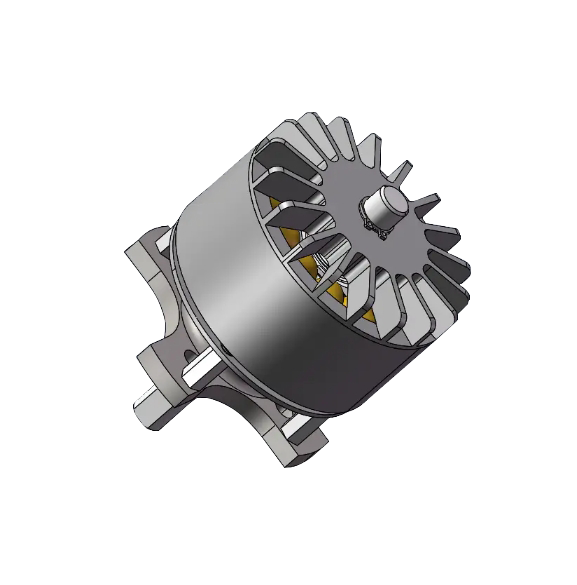

The Iron Core Brushless DC Linear Motor operates on the same principle as a rotary BLDC motor but is unrolled into a flat structure.

The Iron Core design means the coils (primary stage) are wound around iron laminations, which provides a path for the magnetic flux. This results in the highest possible continuous force density for the physical footprint, due to the efficiency of the magnetic circuit. They offer fast, precise, and maintenance-free linear motion over potentially unlimited stroke lengths, making them a premium replacement for ball screw systems in high-throughput machinery.

Introduction

Detailed Parameters and Performance Data

RETEK: High-Throuhgput, Gantry and Machining Drives

Suzhou Retek Electric Technology Co., Ltd. provides iron core linear motors for heavy-duty, high-velocity, and large-format automation systems. We specialize in minimizing the cogging force (the inherent force ripple caused by the iron core interacting with the magnets) through advanced coil design and electronic compensation, ensuring the motion is as smooth as possible despite the high force output.

Applications

Advanced Technology Highlights

Industrial High-Force Linear Motion Applications

- High-Speed Gantry Systems: Drives for large-format CNC machines, laser cutters, and water jet tables. Challenge: High force and precision over long axes.

- Automated Welding and Dispensing: High-dynamic actuators requiring precise velocity control over long strokes.

- Material Handling & Sorting: Fast, long-stroke movers in logistics and packaging.

- Punching and Forming: Actuators requiring very high continuous force for pressing or shaping.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters (Iron Core Linear Motor)

| Parameter | Range / Typical Value | Unit |

| Type | Brushless DC, Iron Core | Design |

| Continuous Force Density | Highest Density | Rating |

| Max Velocity | Up to 10 | m/s |

| Cogging Force | Present (Minimized via Control) | Characteristic |

| Feedback | Linear Encoder (Required) | Type |

Additional Information

Supplementary Details & Notes

Production & Customization Services

Manufacturing includes precise coil winding and potting to minimize air gaps. Thermal imaging under load is used to optimize the continuous force rating.

- Custom Force Density: Adjusting the coil wire gauge and lamination stack to meet specific continuous or peak force requirements.

- Magnet Track Length: Supplying custom-length magnet tracks and end caps for application-specific stroke requirements.

- Cooling Options: Offering integrated water-cooling channels in the primary stage for maximum force output in continuous duty cycles.

- Integrated Cable Management: Providing complete systems with drag chains and pre-wired linear encoders for plug-and-play installation.

About Jiangsu Retek Motion Co., Ltd.

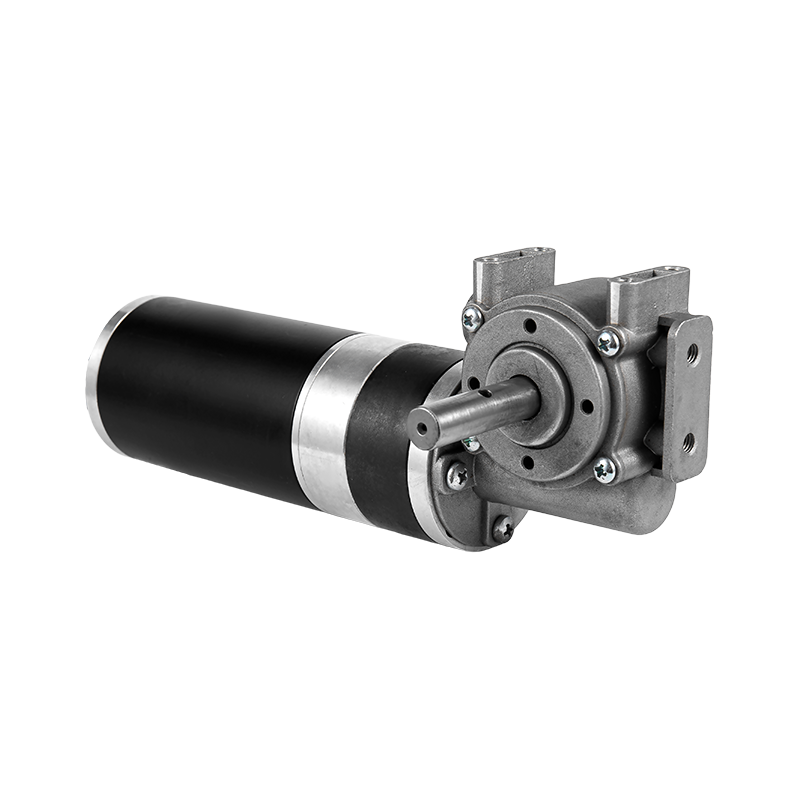

As China Brushless DC Linear Motor Iron Core High Force Manufacturers and Wholesale Brushless DC Linear Motor Iron Core High Force OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español