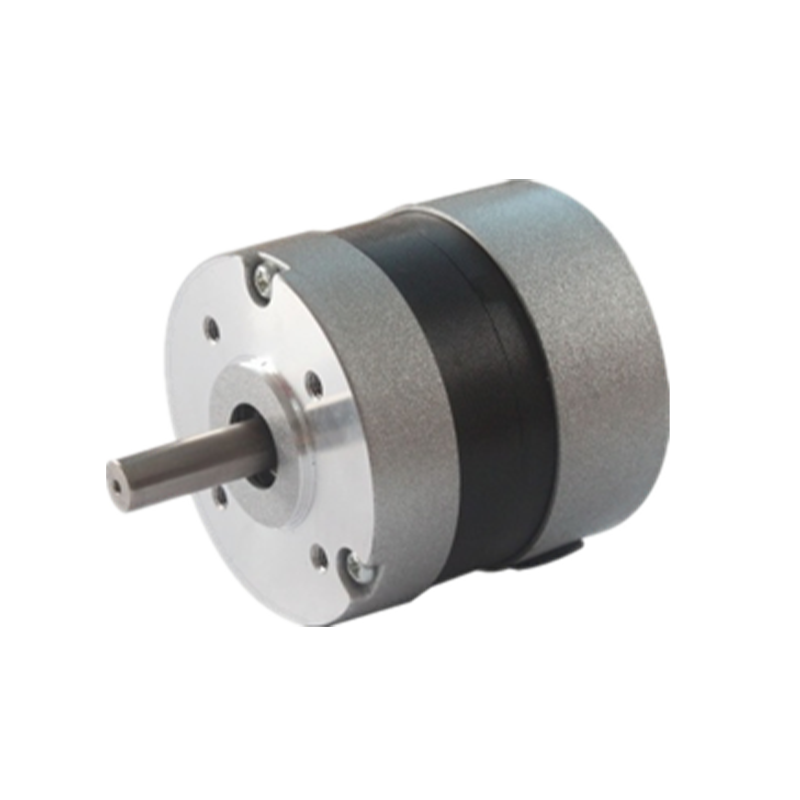

Mechatronic Integration: BLDC Motor with Embedded Drive System

The integrated controller BLDC motor, also known as a mechatronic drive, represents a paradigm shift toward decentralized control in automation. The entire power and logic stage is enclosed within the motor housing or the rear endcap.

This architecture eliminates the complexity and cost of shielded cabling and external cabinet space. The controller hardware, often a specialized MOSFET bridge, is mounted to utilize the motor's metal frame as a passive heat sink, which requires precise thermal coupling. The embedded firmware is pre-calibrated to the specific motor's back-EMF profile, ensuring optimal commutation timing across all operating conditions and significantly increasing system efficiency compared to generic, externally parameterized drives.

Advanced features include internal position counting, closed-loop speed control, and multi-protocol communication (e.g., Industrial Ethernet, CANopen) integrated onto the single PCB.

Introduction

Detailed Parameters and Performance Data

RETEK: Enabling Distributed Intelligence in Motion Control

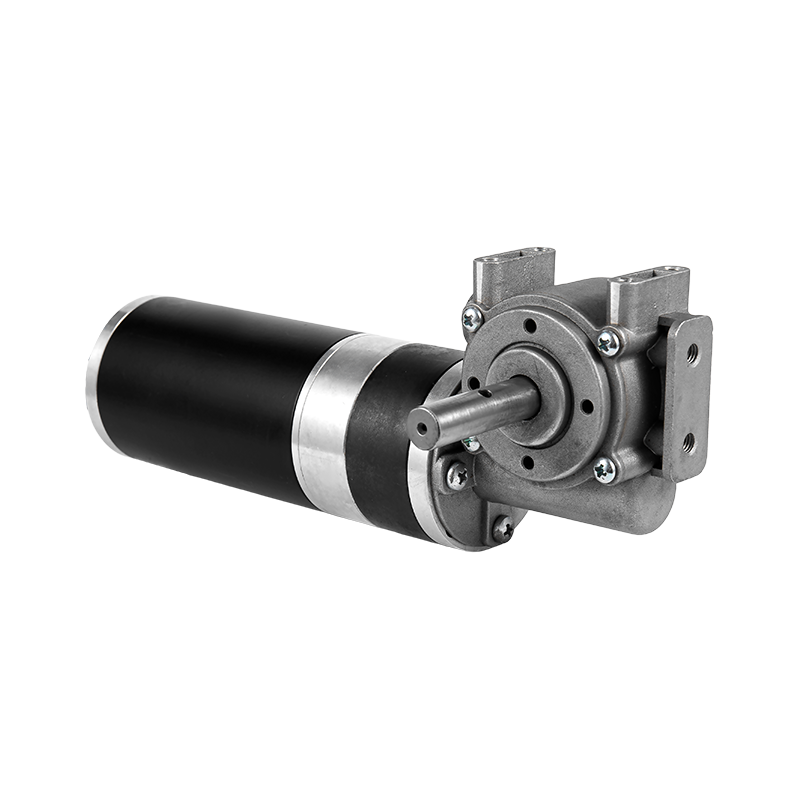

Suzhou Retek Electric Technology Co., Ltd. views motion control as a system, not just a component. Our integrated controller series (W70, EC fan motor) provides our customers with "smart power" solutions. This is particularly advantageous for large-scale distributed systems, such as building automation (HVAC) and remote energy installations (Solar Panel systems). By providing dual-voltage compatibility (230VAC/12VDC into one drive), we offer a highly flexible solution, reducing inventory and simplifying global deployment for our OEM partners.

Applications

Advanced Technology Highlights

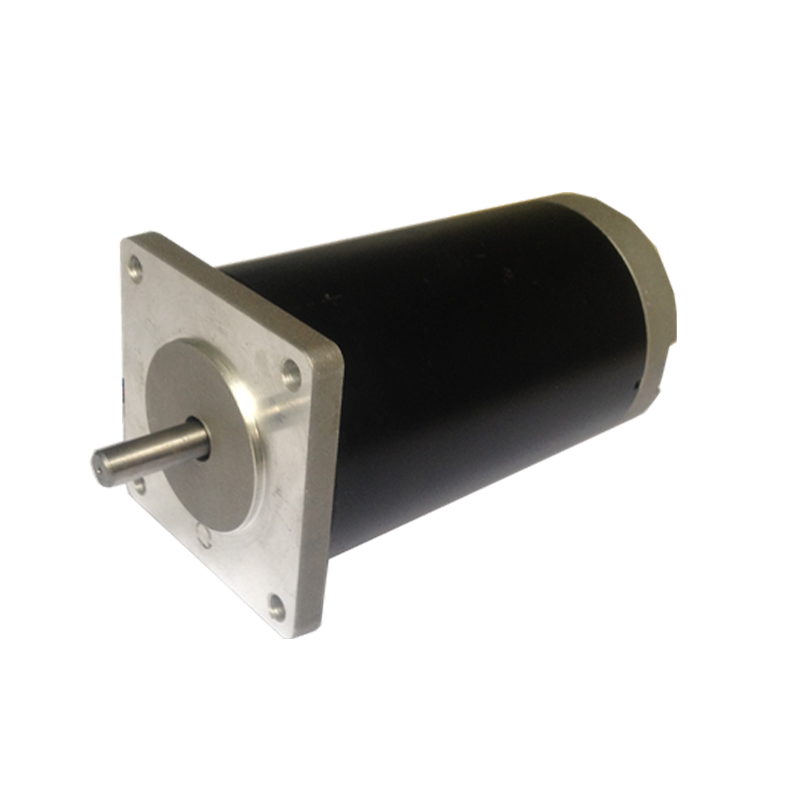

Decentralized Systems and Implementation Scenarios

- Building Automation and HVAC: EC fan motors for roof air ventilators and air handling units, where the integrated controller enables constant airflow control and direct communication with a Building Management System (BMS). Challenge: High reliability and long life for continuous, unattended operation.

- Remote Power Applications: Pumps and actuators in off-grid solar or telecommunication sites (e.g., W70 Series with metal shell). The dual-voltage drive allows seamless transition between solar DC power and generator/grid AC power. Challenge: Extreme temperature fluctuations and high IP requirements.

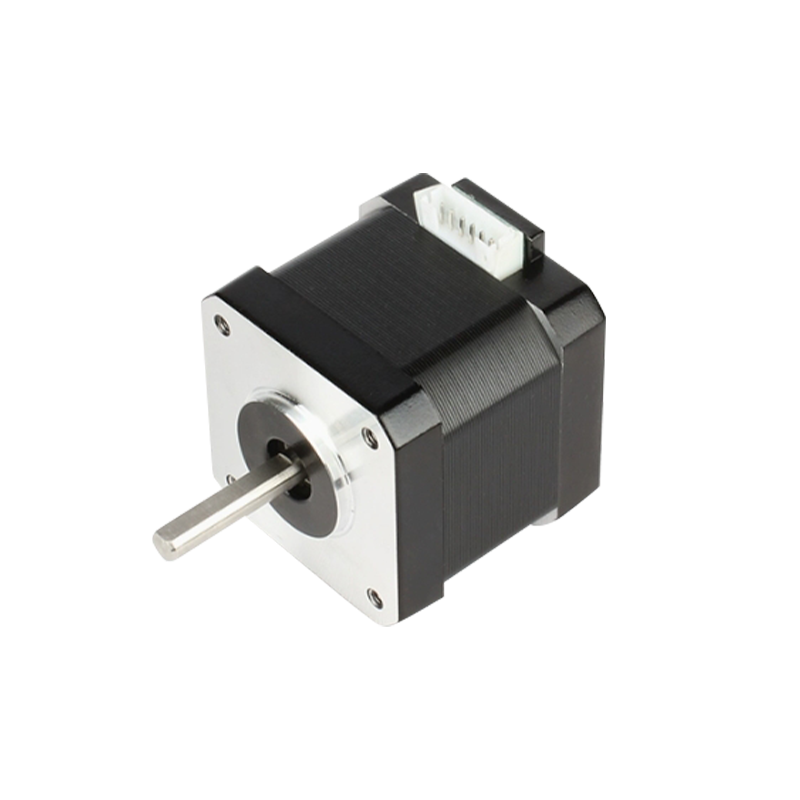

- Modular Machine Design: Conveyor segments or pick-and-place stations that are easily reconfigured. The integrated drive allows for rapid plug-and-play installation without external cabinet wiring.

- Medical Infusion Pumps: Requiring precise, quiet motor control where the compact, integrated design simplifies portable system assembly.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters

| Parameter | Range / Typical Value | Unit |

| Integrated Power Rating | Up to 1.5 | kW |

| Input Voltage Versatility | 12-48 VDC / 100-240 VAC | V/VAC |

| Fieldbus Compatibility | CANopen, RS485, Modbus RTU | Protocol |

| Feedback Integration | Internal Hall/Encoder or Sensorless | Method |

| Temperature Rating (Ambient) | -30 to +60 | °C |

| Safety Features | STOS, STO (Safe Torque Off) ready | Standard |

Additional Information

Supplementary Details & Notes

Integrated Production and Customization Workflow

Our production includes automated testing of the controller-motor interface, verifying current ripple, thermal behavior, and communication integrity across the full load range. This simultaneous testing ensures the integrated system is validated as a whole.

- Fieldbus/Protocol Implementation: Customizing the communication stack to support non-standard baud rates or specific data payload formats required by the client’s industrial network.

- Custom I/O Configuration: Modifying the digital and analog input/output configuration for interfacing with external limit switches, potentiometers, or safety circuits.

- Software Parameter Locking: Offering services to lock specific motor parameters in the firmware (e.g., speed limit, max current) to protect the end-system from unauthorized adjustment or misuse.

- Integrated Braking: Due to space constraints, integrated motors often use a dynamic braking circuit within the controller instead of an external mechanical brake. We can tailor the dynamic braking rate.

About Jiangsu Retek Motion Co., Ltd.

As China Integrated Controller BLDC Motors Manufacturers and Wholesale Integrated Controller BLDC Motors OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español