High Voltage DC Motor: Powering Industrial and Medical Equipment

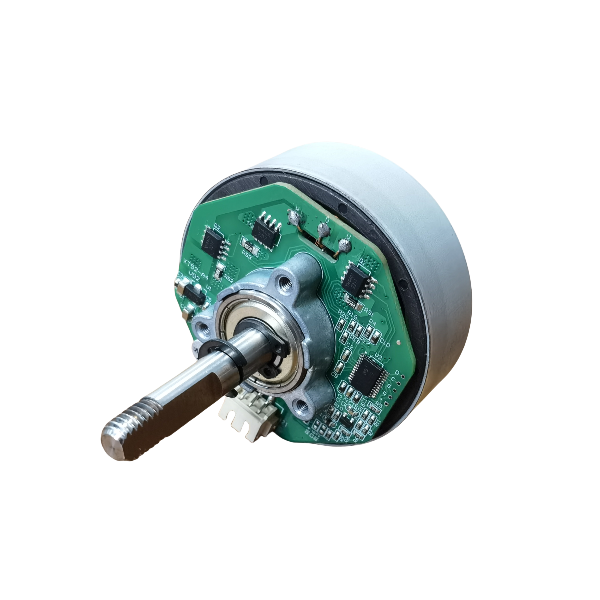

The High Voltage DC Brushed Motor is specifically designed to operate on elevated DC supply voltages (e.g., 90V, 180V, 240V), bypassing the limitations of standard low-voltage DC motors (12V/24V).

Running at high voltage drastically reduces the required operating current for a given power output (P=V⋅I). This allows for the use of thinner wiring, less power loss (I2R), and enables the motor to deliver significant power (up to several horsepower) over longer distances, making it ideal for large fixed industrial machines that convert standard AC mains to high DC voltage via a rectifier bridge.

Introduction

Detailed Parameters and Performance Data

RETEK: High Power Efficiency and Cost-Effective Drive

Suzhou Retek Electric Technology Co., Ltd. provides high-voltage DC motors for applications demanding robust, easily controlled speed and torque. By optimizing the armature winding and using high-grade insulation, we ensure safety and efficiency at elevated voltages. These motors are traditionally paired with inexpensive SCR/Thyristor drives, offering a cost-effective solution for variable speed control in heavy machinery.

Applications

Advanced Technology Highlights

Fixed Installation Applications for High Voltage DC Motors

- Large Treadmills/Fitness Equipment: Drives requiring high, sustained power from standard wall outlets. Challenge: High power in a small frame.

- Industrial Mixers and Agitators: Motors requiring high torque and variable speed control in fixed factory setups.

- Medical X-Ray/Imaging Tables: Actuators requiring smooth, high-force positioning.

- Printing and Converting Presses: Motors for synchronized material feed and roller drives.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters (High Voltage DC)

| Parameter | Range / Typical Value | Unit |

| Operating Voltage | 90 to 240 | VDC |

| Output Power | 0.5 to 2 | HP |

| Rated Current | Low (E.g., 180V/5A) | Amps |

| Speed Control | SCR/Thyristor (Cost Effective) | Type |

| Commutation | Carbon Brush | Feature |

Additional Information

Supplementary Details & Notes

Production & Customization Services

Production includes winding tests for insulation resistance at high potential (Hi-Pot test) to guarantee safety and compliance with international standards.

- Custom Armature Winding: Adjusting the winding configuration to perfectly match specific rectified voltages (e.g., 170VDC from 120VAC supply).

- Integrated Thermal Protection: Factory installation of thermal cutoffs or thermistors into the winding for driver safety monitoring.

- Custom Flange/Mounting: Providing customized face and base mounts to match existing equipment footprint for easy retrofit.

- Integrated Cooling: Providing external forced-air cooling options (TEFC - Totally Enclosed Fan Cooled) for demanding continuous duty cycles.

About Jiangsu Retek Motion Co., Ltd.

As China High Voltage DC Brushed Motor 90V 180V Manufacturers and Wholesale High Voltage DC Brushed Motor 90V 180V OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español