1. Introduction: Deconstructing AC Induction Motor Horsepower The AC Induction Motor is one of the m...

READ MOREIndustry News

2026-01-08

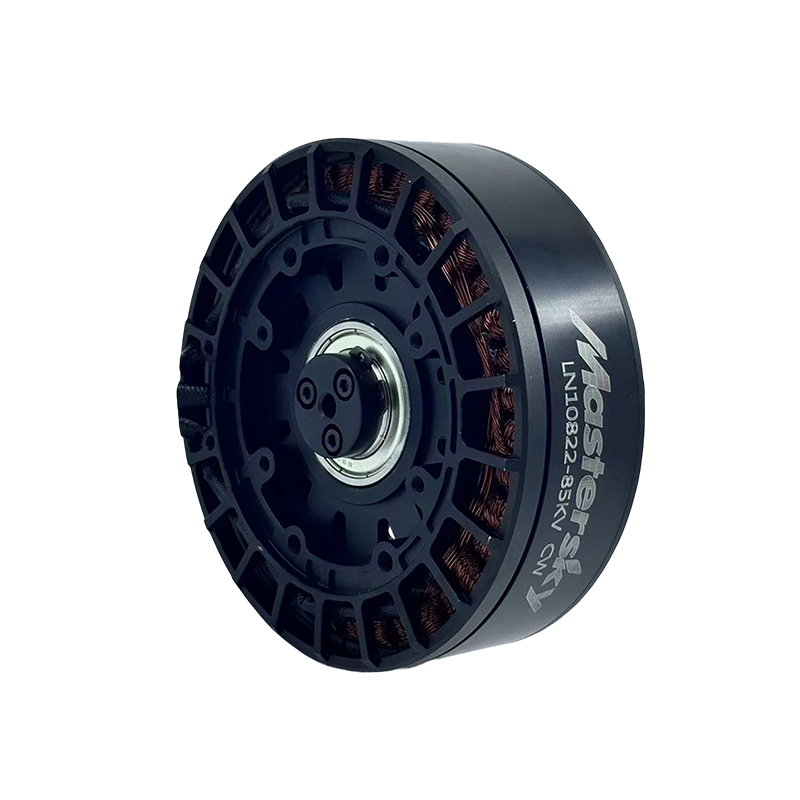

In the rapidly evolving world of unmanned aerial vehicles (UAVs), the heart of performance lies in the propulsion system. At the core of this system are drone brushless motors, the sophisticated components responsible for converting electrical energy into precise mechanical thrust. Unlike their brushed counterparts, brushless motors offer superior efficiency, longevity, and power-to-weight ratios, making them the undisputed standard for commercial, industrial, and high-performance hobbyist drones. This guide delves deep into the technology, provides actionable selection advice, and explores how modern custom engineering is shaping the future of UAV propulsion.

To appreciate the advantages of brushless motors, one must first understand their fundamental design and operation principles.

The absence of physical brushes eliminates friction, sparking, and wear, leading to the motor's hallmark benefits.

The superiority of brushless motors can be summarized in their operational efficiency and durability.

For instance, brushless motors are significantly more efficient, often operating at 85-90% efficiency compared to 75-80% for brushed motors. This directly translates to longer flight times.

| Feature | Brushless Motor | Brushed Motor |

|---|---|---|

| Efficiency | High (85-90%) | Moderate (75-80%) |

| Lifespan | Very Long (1000s of hours) | Short (100s of hours) |

| Maintenance | Very Low | High (brush replacement) |

| Power-to-Weight Ratio | Excellent | Good |

| Control Precision | Excellent | Good |

Selecting the optimal motor is a balancing act between your drone's intended use and its physical and electrical parameters.

The application dictates the motor's characteristics. For example, a motor suitable for a heavy-lift cinematography drone would be vastly different from one designed for a racing FPV drone.

A cinematography drone requires high-torque, low-KV motors for smooth and stable lift with large propellers, whereas an FPV racing drone demands ultra-responsive, high-KV motors for explosive acceleration and rapid directional changes.

| Drone Application | Recommended Motor Type | Primary Focus |

|---|---|---|

| Aerial Photography/Cinematography | Low KV, Large Stator | Stability, Smoothness, Efficiency |

| FPV Racing | High KV, Medium Stator | Thrust-to-Weight, Responsiveness |

| Long-Endurance/Industrial Inspection | Low KV, Optimized Efficiency | Maximum Flight Time, Reliability |

| Heavy-Lift & Delivery | Very Low KV, Very Large Stator | Maximum Torque and Power |

Even with the right motor, understanding how to increase drone motor efficiency and address common problems is key to reliable operation.

Common issues often stem from physical damage, electrical faults, or incompatible components. Recognizing the signs of signs of drone motor failure early can prevent a catastrophic crash.

Proactive care is essential for safety and longevity. Understanding drone motor maintenance steps is a non-negotiable aspect of professional drone operation.

While standard motors serve many applications, cutting-edge and specialized drone missions often push the limits of catalog components. This is where the true engineering partnership begins.

Standard motors represent a compromise, designed for broad appeal. They may not meet the exact needs of a drone requiring unique torque curves, specific thermal characteristics, or integration with non-standard frames and systems.

Unlike other motor suppliers, Retek engineering system prevents the selling of our motors and components by catalogue as every model is customized for our customers. The customers are assured that every component they receive from Retek is designed with their exact specifications in mind. Our total solutions are a combination of our innovation and a close working partnership with our customers and suppliers.

This approach is vital when addressing complex challenges like preventing drone motor overheating in confined spaces or designing a motor system that meets the stringent weight reduction for longer drone flights targets without sacrificing durability. Retek's integrated platforms—encompassing Motors, Die-Casting and CNC manufacturing, and wire harness—allow for a holistic design process. From the initial electromagnetic simulation of the motor to the precision machining of its housing and the custom wiring that connects it, every aspect is controlled and optimized as one cohesive system. This ensures not just a motor, but a perfectly integrated propulsion solution that delivers reliable performance for demanding applications in sectors such as industrial inspection, aerial logistics, and specialized automotive and aerospace systems.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

The KV rating indicates how many revolutions per minute (RPM) the motor will turn per volt applied, with no load. A lower KV motor produces more torque and is better for larger propellers, while a higher KV motor spins faster and is suited for smaller props on agile drones.

Signs of drone motor failure include excessive heat even under normal load, increased vibration or grinding noises, visible physical damage like a bent shaft, loss of power, or intermittent stuttering during operation. Regular inspection can help identify these issues early.

Focus on how to increase drone motor efficiency through proper propeller matching and using high-quality, low-resistance ESCs and batteries. Crucially, implement a strategy of weight reduction for longer drone flights by using lighter components and only carrying essential payload.

Basic visual and cleaning maintenance should be done before and after every flight session. A more thorough check of bearings and connections should be performed every 20-30 flight hours. Following a consistent set of drone motor maintenance steps is the best practice for longevity.

Rapid overheating is often a symptom of an over-propped motor (too large/heavy a propeller), an ESC that cannot deliver sufficient current cleanly, or flying in an overly aggressive manner that keeps the motor at peak load. Preventing drone motor overheating requires checking component compatibility and ensuring adequate cooling airflow around the motors.

1. Introduction: Deconstructing AC Induction Motor Horsepower The AC Induction Motor is one of the m...

READ MORE1. Introduction In modern industrial automation, data center construction, consumer electronics upgr...

READ MOREStepper motors represent a cornerstone of modern motion control, offering precise positioning and re...

READ MOREThe industrial motor landscape is undergoing a significant transformation, driven by the relentless ...

READ MORE