60mm Low-Inertia AC Servo: Rapid Acceleration and Deceleration

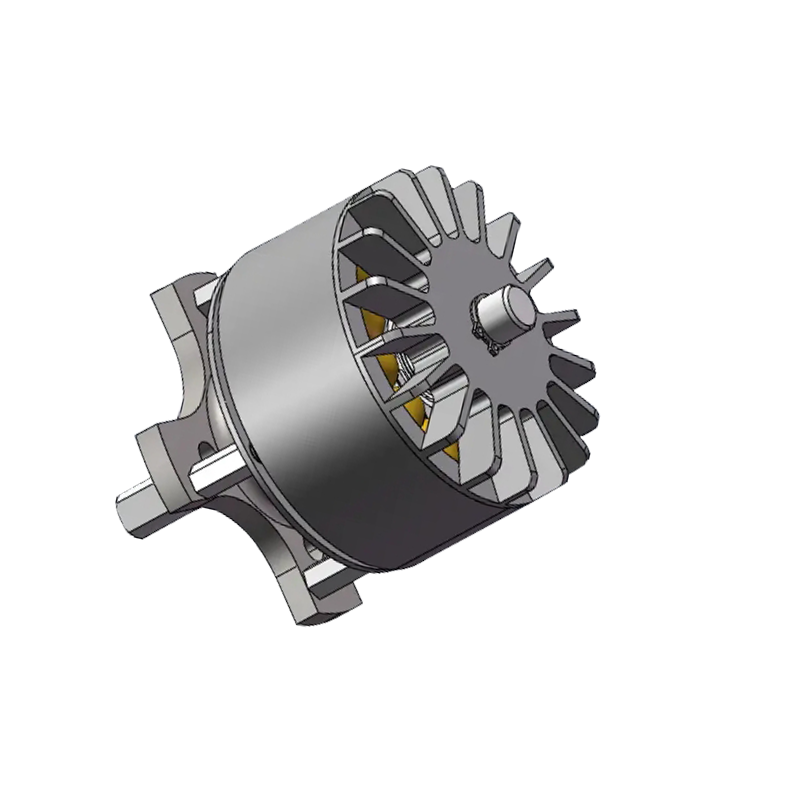

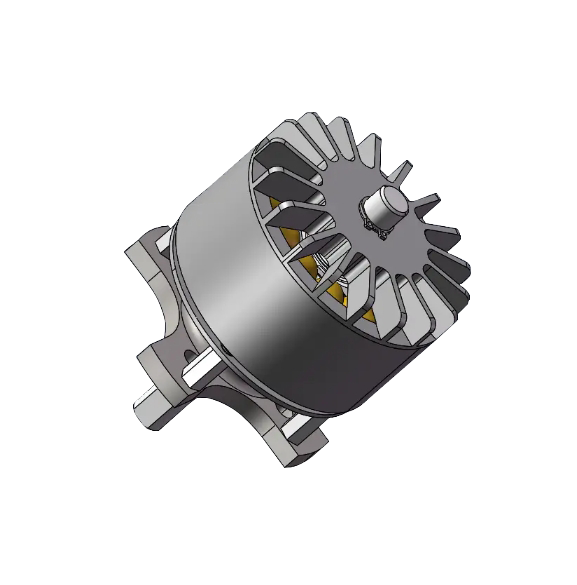

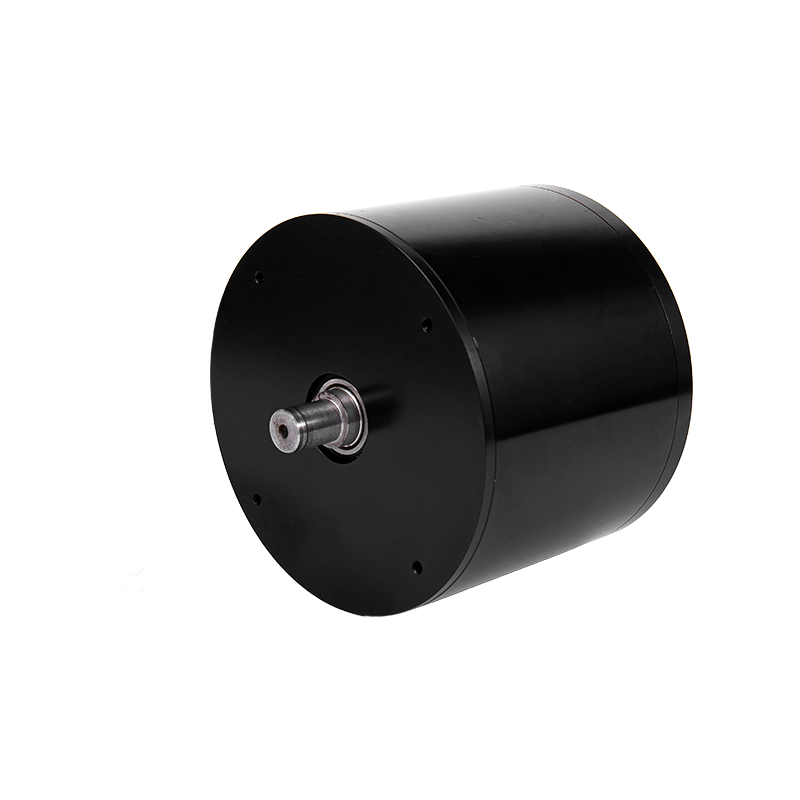

The 60mm Low-Inertia AC Servo Motor is designed with a small rotor diameter and a longer axial length (high L/D ratio). This design drastically reduces the rotor's Moment of Inertia (Jm).

A low inertia rotor enables extremely high acceleration and deceleration rates (rad/s2) with minimal current draw, making it ideal for tasks that require rapid, repetitive point-to-point movements (e.g., pick-and-place, vision systems). While the continuous torque is moderate, the peak torque is often 3 to 5 times the continuous rating, allowing the motor to achieve instant bursts of high force for dynamic motion.

Introduction

Detailed Parameters and Performance Data

RETEK: Velocity Control for High-Speed Automation

Suzhou Retek Electric Technology Co., Ltd. positions this low-inertia servo for the cutting edge of industrial automation, including high-speed assembly and semiconductor handling. We match this motor with high-bandwidth, digital servo drives to fully exploit its dynamic capabilities. Our focus is on providing a balanced magnetic design that minimizes cogging torque, ensuring smooth control even during the most demanding velocity changes.

Applications

Advanced Technology Highlights

High-Speed, Intermittent Applications for Low-Inertia Servos

- Pick-and-Place Robotics (Delta Robots): Motors for highly repetitive, high-acceleration joint movements. Challenge: Maximize throughput (cycles per minute).

- Vision and Inspection Systems: Motors for rapidly indexing mirrors or moving camera optics.

- Semiconductor Wafer Handling: Motors for transport arms requiring ultra-fast, vibration-free moves.

- Automated Assembly Machines: Drives for indexers and component placement heads.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters (60mm Low Inertia Servo)

| Parameter | Range / Typical Value | Unit |

| Frame Size | 60 | mm |

| Rotor Inertia (Jm) | Ultra-Low | kg ⋅ m$^2$ |

| Peak Torque Multiplier | 300 to 500 | % of Rated |

| Max Speed | 5,000 to 7,000 | RPM |

| Feedback | High-Resolution Absolute Encoder | Type |

Additional Information

Supplementary Details & Notes

Production & Customization Services

Production includes advanced automated winding techniques to achieve the small rotor profile and a mandatory dynamic test to confirm the Torque-to-Inertia ratio specification.

- Custom Encoder/Feedback: Providing specific industrial bus protocols (e.g., EtherCAT, PROFINET) via the integrated absolute encoder.

- Integrated Low-Backlash Gearbox: Pre-assembling with a miniature low-backlash planetary gearhead to increase output torque while maintaining dynamic performance.

- Custom Shaft Configuration: Providing custom shafts for specific high-speed coupling requirements (e.g., feather keys, specialized flanges).

- Thermal Monitoring: Integration of KTY or PTC thermistors for winding temperature monitoring by the drive.

About Jiangsu Retek Motion Co., Ltd.

As China High Dynamic AC Servo Motor 60mm Low Inertia Manufacturers and Wholesale High Dynamic AC Servo Motor 60mm Low Inertia OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español