Principles of Permanent Magnet DC Shunt Brush Motors

The Permanent Magnet (PM) DC Shunt Motor, historically less common than series or compound windings, offers a blend of high starting torque (like a series wound) and stable speed regulation (like a shunt wound). In a PM configuration, the field is provided by the magnets, and the "shunt" designation refers to the electrical characteristics achieved by specific armature winding and brush placement.

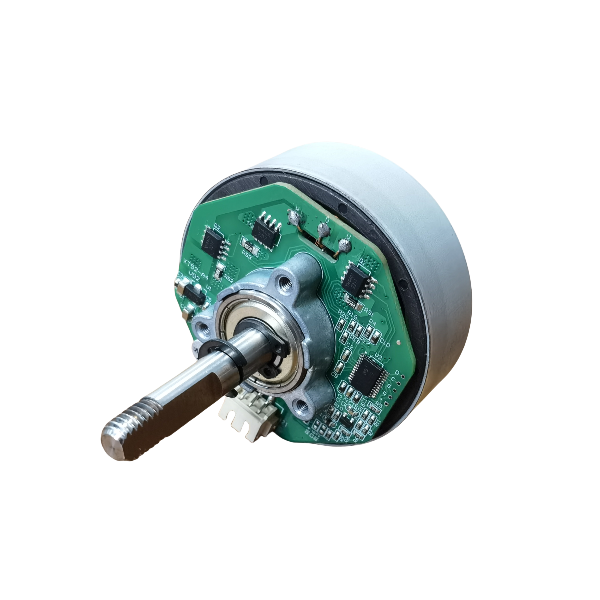

The 78mm frame provides a high magnetic flux path, resulting in high efficiency for a brushed type. The Slot Type Commutator refers to the traditional segmented copper construction, providing robust current switching. This motor is valued for its relatively flat speed-torque curve, making it suitable for applications that must maintain speed despite load changes.

Introduction

Detailed Parameters and Performance Data

RETEK: High-Efficiency Brushed Alternatives

Suzhou Retek Electric Technology Co., Ltd. supplies this specialized PM Shunt Brush Motor for clients who require the simple control of a brushed motor but need improved speed stability over a standard PMDC motor. By optimizing the magnetic circuit and commutator/brush material pairing, we maximize the motor's operating envelope and minimize maintenance intervals, providing a high-performance alternative for high-reliability industrial controls.

Applications

Advanced Technology Highlights

Niche Applications for PM DC Shunt Motors

- Process Mixer and Agitator Drives: Applications where the motor must maintain a relatively constant speed regardless of changes in fluid viscosity or load. Challenge: Speed stability under varying load.

- Precision Conveying Systems: Where consistent belt speed is critical for quality control or sorting.

- Tensioning Systems: Actuators for winding or unwinding materials (paper, film) requiring stable tension via speed regulation.

- Calibration and Testing Equipment: Requiring repeatable speed for reference tests.

Technical Specifications

Industrial & Commercial Usage

Technical Parameters (PM DC Shunt Motor)

| Parameter | Range / Typical Value | Unit |

| Outer Diameter | 78 | mm |

| Speed Regulation | Improved vs. Standard PMDC | Factor |

| Commutator Type | Slot Type, High Segment | Design |

| Efficiency | Optimized High | % |

| Torque Characteristics | High Starting, Stable Operating | Profile |

| Nominal Voltage | 24 to 48 | VDC |

Additional Information

Supplementary Details & Notes

Integrated Production and Customization Workflow

Production focuses on precise winding symmetry to ensure balanced performance and stable speed regulation. Each motor undergoes a load test to verify its speed-torque characteristics against the published curve.

- Winding Profile: Fine-tuning the armature winding to achieve a specific KV (back EMF constant) for high-precision speed stability requirements.

- Commutator Profile: Offering custom segment numbers or undercut depth to optimize for specific brush types or operating environments (e.g., high altitude).

- Gearhead Compatibility: Providing specific mounting faces and output shaft modifications for direct coupling with high-precision, low-backlash gearheads.

- Thermal Sensors: Integration of internal thermal cut-offs (TCOs) or thermal protection switches for safety in critical, continuous operation.

About Jiangsu Retek Motion Co., Ltd.

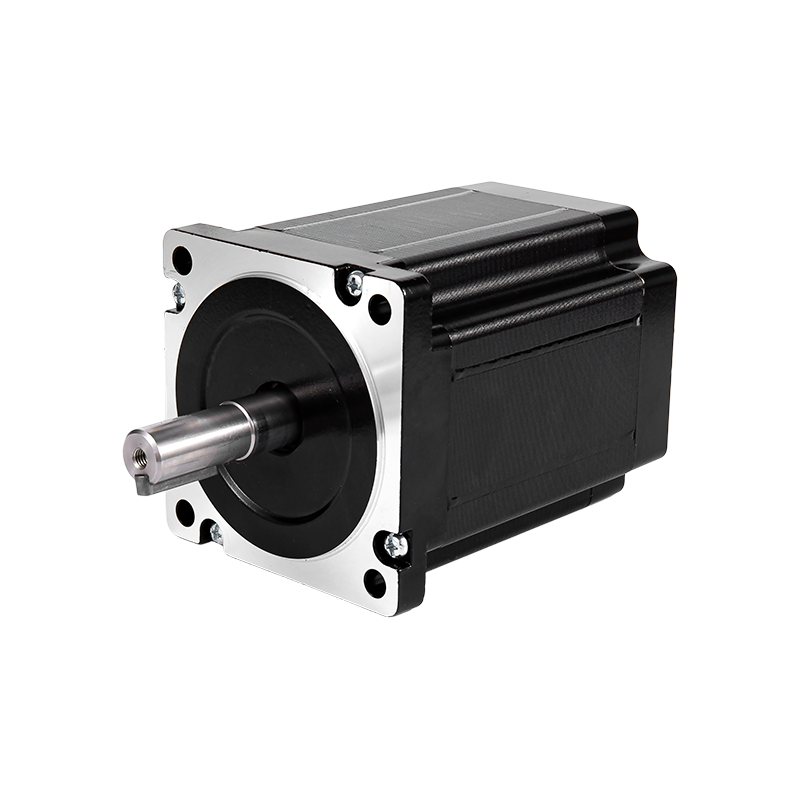

As China Permanent Magnet Dc Shunt Brush Motor 78mm Diameter with Slot Type Commutator Manufacturers and Wholesale Permanent Magnet Dc Shunt Brush Motor 78mm Diameter with Slot Type Commutator OEM/ODM Suppliers, Retek business consists of three platforms: Motors, Die-Casting and CNC manufacturing and wire harness. Retek products are widely supplied for residential fans, vents, boats, airplanes, medical facilities, laboratory facilities, trucks and other automotive machines.

Welcome to send us an RFQ, it is believed you will get the best cost-effective products and services here!

Get in touch

Get in touch

English

English Deutsch

Deutsch 中文简体

中文简体 Español

Español