1. Introduction: Deconstructing AC Induction Motor Horsepower The AC Induction Motor is one of the m...

READ MOREIndustry News

2025-09-23

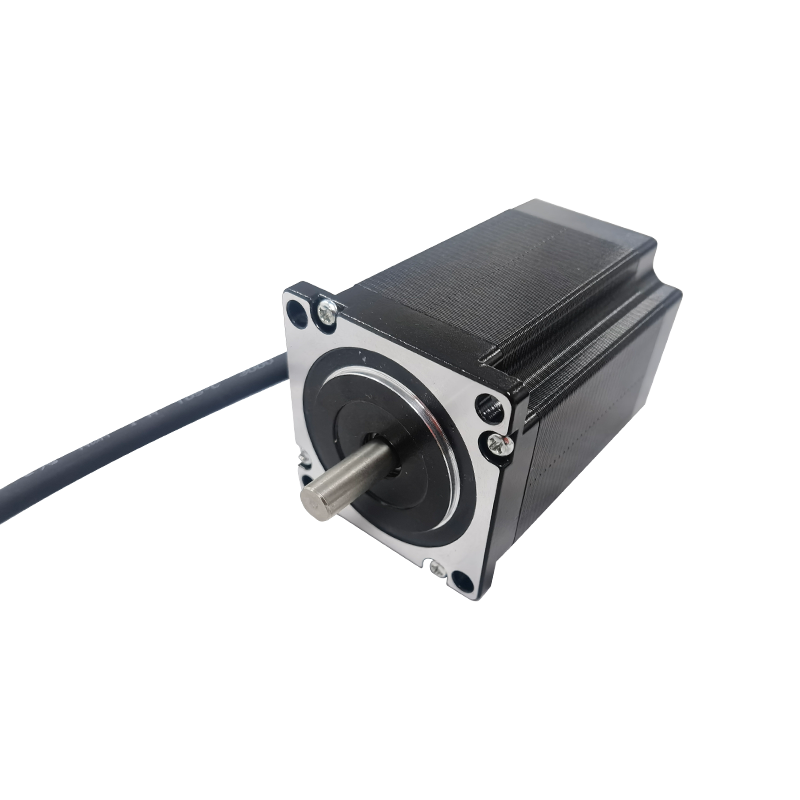

Stepper motors represent a cornerstone of modern motion control, offering precise positioning and repeatability without the need for complex feedback systems. These brushless, synchronous electric motors convert digital pulses into precise mechanical shaft rotations, moving in discrete steps. This characteristic makes them indispensable in applications ranging from consumer electronics to sophisticated industrial machinery. However, when applications demand not only precision but also significant force to move heavy loads, overcome friction, or maintain position under stress, a standard stepper motor may prove insufficient. This is where the category of high torque stepper motors becomes critical.

In the context of stepper motors, ‘high torque’ refers to the motor’s ability to generate a superior rotational force compared to standard motors of a similar physical size or frame. Torque is the fundamental measure of a motor’s strength, dictating how much load it can accelerate, drive, and hold stationary. The importance of high torque cannot be overstated in demanding applications. For instance, in robotics, high torque is essential for joint actuators that must support the weight of a robotic arm and its payload. In CNC machining, it ensures the cutting tool can move precisely through material without stalling. Essentially, high torque stepper motors bridge the gap between the need for pinpoint accuracy and the requirement for substantial mechanical power, enabling innovation in fields that demand both.

To fully appreciate the advantages of high torque stepper motors, one must first understand the basic principles governing all stepper motors. Unlike standard DC motors that spin continuously when voltage is applied, a stepper motor moves in fixed angular increments known as steps. The motor’s internal structure consists of a stationary part (the stator) with multiple electromagnetic coils and a rotating part (the rotor) typically containing permanent magnets or a magnetically permeable core. By energizing the stator coils in a specific sequence, a magnetic field is created that attracts the rotor, causing it to align with the field and thus rotate by a precise angle with each pulse received from a controller.

There are several fundamental types of stepper motors, each with distinct operational characteristics. Permanent Magnet (PM) stepper motors feature a rotor with permanent magnets, providing a good holding torque and a relatively large step angle, but they often offer lower resolution and torque compared to other types. Variable Reluctance (VR) stepper motors have a soft iron rotor that aligns with the magnetic field path of least reluctance (magnetic resistance); these are less common today. The most prevalent type, especially in high-performance applications, is the Hybrid Stepper Motor. This design combines the principles of both PM and VR motors, utilizing a permanent magnet rotor with teeth that interact with the toothed electromagnetic stator. This hybrid configuration allows for very small step angles, high torque output, and excellent positional accuracy, making it the dominant design for high torque stepper motor applications.

Several key terms are essential for understanding stepper motor specifications. The step angle defines the angular distance the shaft rotates with each single pulse, commonly 1.8° (200 steps/revolution) or 0.9° (400 steps/revolution) for hybrid motors. Holding torque is the maximum torque the motor can exert when stationary with its windings energized, which is a critical rating for a high torque stepper motor as it indicates its ability to hold a position against an external force. Conversely, detent torque is the torque present when the motor windings are not energized, caused by the magnetic interaction between the permanent magnet rotor and the stator; this provides a slight passive holding force.

In mechanical terms, torque is a measure of the rotational force applied to an object. For a stepper motor, it is the rotational force the motor shaft can generate to cause or resist movement. It is analogous to the concept of force in a linear system. High torque, therefore, signifies a motor’s capacity to produce a strong rotational force. This is paramount for applications that involve accelerating heavy loads, driving mechanisms with high friction, or maintaining precise positioning under constant external pressure. It is important to distinguish that a high torque stepper motor is not necessarily a different category of motor but rather a designation for stepper motors engineered to deliver torque values significantly above the standard baseline for their frame size.

Torque in stepper motors is typically measured in Newton-meters (N·m) or ounce-inches (oz-in). The most important torque specification found on a motor’s datasheet is the holding torque. This is the maximum torque the motor can produce at standstill when its coils are fully energized. It serves as a primary indicator of the motor’s strength. Another crucial representation is the torque curve, a graph that plots the motor’s available torque against its rotational speed. This curve is vital because a stepper motor’s torque decreases as its speed increases due to the effects of inductance and back EMF. Understanding the stepper motor speed vs torque relationship is essential for selecting a motor that will perform adequately across the entire required operating range of an application, ensuring it does not stall at higher speeds.

The torque output of a stepper motor is not a fixed value; it is influenced by several operational and design factors. The current supplied to the motor windings is a primary driver; higher current generally results in a stronger magnetic field and thus higher torque, up to the motor’s design limits. The supply voltage also plays a critical role, particularly at higher speeds. A higher voltage allows the current to change direction in the motor windings more quickly, helping to maintain torque at increased rotational speeds. The motor’s physical design, including the quality of its magnetic materials, the number of stator teeth, and the air gap between the rotor and stator, are all engineered to maximize torque generation. For example, a NEMA 23 high torque stepper motor will be designed with these factors optimized to deliver more torque than a standard NEMA 23 motor.

The primary advantage of utilizing a high torque stepper motor is the significant increase in mechanical power available for motion control tasks. This enhanced capability translates into several key benefits that are critical for the success of demanding applications. The most evident benefit is the ability to handle larger inertial loads and overcome substantial friction. In systems like CNC routers or automated conveyor belts, the motor must not only move the toolhead or belt but also rapidly accelerate and decelerate the mass. A motor with insufficient torque would stall or lose steps under such demands, whereas a high torque stepper motor provides the necessary force to ensure reliable operation, thereby expanding the range of possible applications and improving the robustness of existing ones.

Improved accuracy and a significant reduction in positional errors are another major advantage. The high holding torque characteristic of these motors allows them to maintain their position rigidly against unexpected external forces or vibrations. This is crucial in applications like precision assembly or medical device positioning, where even a minute deviation can lead to failure. Furthermore, the substantial torque reserve helps prevent stalling, which is a common cause of lost steps. Lost steps occur when the motor fails to execute a commanded movement, leading to an accumulating positional error that the open-loop system cannot detect. By operating well within its torque capacity, a high torque stepper motor greatly minimizes this risk, ensuring that the actual position of the machine always matches the intended position commanded by the controller.

Finally, these motors offer greater design flexibility and longevity. Engineers are not forced to push a motor to its operational limits, which often leads to overheating and reduced lifespan. Instead, they can select a high torque stepper motor that operates efficiently and coolly within its performance envelope. This headroom also allows systems to handle variable loads or unexpected obstructions more gracefully without catastrophic failure. The ability to use a more compact motor frame, such as a NEMA 23 high torque stepper motor, to achieve the performance that might otherwise require a larger, more cumbersome frame, is a direct benefit of this technology, enabling more streamlined and efficient mechanical designs.

The unique combination of precision, reliability, and power makes high torque stepper motors suitable for a vast array of applications across numerous industries. Their ability to provide controlled motion in discrete steps without feedback sensors simplifies system design while ensuring accuracy.

In the field of Robotics, these motors are the actuators of choice for joint movement, particularly in robot arms that must handle heavy payloads. The high torque stepper motor for robotics provides the necessary force to articulate limbs and grippers precisely while supporting the weight of the arm itself and the object it is carrying. This is essential for tasks ranging from industrial assembly and welding to complex laboratory automation. The holding torque ensures that the arm can maintain its position without drifting, even when powered on but not in motion.

CNC Machines represent a classic application where precision and power are non-negotiable. A stepper motor for CNC router applications must move the cutting tool through materials like metal, wood, or plastic, encountering significant resistance. The high torque stepper motor ensures that the toolpath is followed accurately without stalling, which would ruin the workpiece and potentially damage the machine. The same principles apply to other CNC equipment such as lathes, plasma cutters, and laser cutters, where consistent performance is critical for quality and productivity.

The world of 3D Printing relies heavily on stepper motors for both axis movement and filament extrusion. As printers increase in size and speed, and as materials like ABS and nylon require more force to push through the extruder, the demand for torque rises. A stepper motor for 3D printers high torque ensures precise layer alignment by preventing missed steps on the X, Y, and Z axes, while a high-torque extruder motor provides consistent filament flow, leading to higher print quality and reliability.

Industrial Automation is a broad domain where these motors are ubiquitous. They drive conveyor systems in packaging machinery, actuate valves, and position components in pick & place machines. In these environments, durability and continuous operation are paramount. The use of an industrial high torque stepper motor ensures long-term reliability and the ability to perform repetitive tasks with high accuracy millions of times over. For harsh environments, options like an IP65 high torque stepper motor or even an IP67 rated outdoor stepper motor are available to resist dust and moisture ingress.

Medical Equipment demands the highest levels of precision, cleanliness, and reliability. High torque stepper motors are used in devices such as automated analyzers, infusion pumps, surgical robots, and imaging equipment. Their precise movement controls sample handling, dosage delivery, and the positioning of sensors and tools. In many cases, a low noise stepper motor for lab automation or medical use is specified to ensure a quiet operating environment. The predictable nature of stepper motor operation, combined with high torque, makes them ideal for these sensitive applications.

Beyond these, specialized applications are continually emerging. They are used in automotive actuators for mirror adjustment and throttle control, in printing machines for accurate paper feed, and in renewable energy systems such as solar tracker stepper motor high torque units that adjust panels to follow the sun and in wind turbine pitch control mechanisms.

Selecting the appropriate high torque stepper motor for a specific application requires a systematic evaluation of several key parameters. A wrong choice can lead to poor performance, motor stalling, overheating, or premature failure.

The most critical step is accurately determining the application’s torque requirements. This involves calculating the torque needed to accelerate the load’s inertia and to overcome any continuous forces, such as friction or gravity. The motor must provide torque that exceeds the peak torque required by the application throughout the entire operational speed range, as defined by the stepper motor speed vs torque curve. It is a best practice to include a safety margin of 30-50% above the calculated requirement to account for unforeseen variables like friction changes or manufacturing tolerances. Consulting a stepper motor torque chart for a candidate motor is essential to verify that its torque curve meets the application’s demands at both low and high speeds.

The physical size of the motor, often standardized by NEMA frame sizes (e.g., NEMA 17, NEMA 23, NEMA 34), provides a general indication of its power capability. A NEMA 23 high torque stepper motor will typically deliver more torque than a NEMA 17 motor, while a large frame stepper motor like a NEMA 34 will be capable of even higher torque outputs. However, frame size alone is not a perfect indicator; the internal design and quality of materials greatly influence the actual torque. The selection must balance the torque requirement with the available space and mounting constraints within the machine.

Matching the motor’s electrical specifications to the driver and power supply is crucial for achieving the rated performance. The motor’s current rating is the maximum current per phase it can handle without overheating. The driver must be capable of delivering this current. The supply voltage is equally important. A higher voltage allows the current to ramp up quickly in the motor windings, which is necessary to maintain torque at higher speeds. Operating a motor with a power supply that has too low a voltage will result in a rapid drop-off of torque as speed increases, a phenomenon clearly visible on the motor’s torque curve.

The step angle determines the motor’s intrinsic resolution. A standard 1.8° motor provides 200 steps per revolution, while a 0.9° motor provides 400 steps. For applications requiring very fine positional control, a smaller step angle or the use of a driver capable of microstepping is advantageous. It is important to remember that while microstepping increases resolution, it does not significantly increase accuracy; the torque produced at a microstep position is lower than at a full-step position.

The operating environment must be considered to ensure reliability. Factors such as ambient temperature, presence of contaminants like dust or moisture, and exposure to vibrations can impact motor selection. For example, in a wash-down environment or an outdoor application, an IP65 high torque stepper motor or higher would be necessary to prevent damage. High ambient temperatures may require derating the motor (using it below its maximum torque specification) to prevent overheating, or selecting a motor with a higher temperature class.

Selecting a specific model from the vast array of available high torque stepper motors can be daunting. The following overview presents a range of products categorized by their typical application strengths, highlighting key features without referencing specific brand names. This list illustrates the diversity available to engineers and designers.

NEMA 17 High Torque Stepper Motor: This compact motor is a workhorse in applications where space is limited but performance cannot be compromised. It is exceptionally popular in high-end 3D printing and small-scale automation. Modern versions offer torque values that rival larger, older models, making them ideal for precision instruments and compact robotics joints.

NEMA 23 High Torque Stepper Motor: Arguably the most common frame size for demanding benchtop applications, the NEMA 23 high torque stepper motor provides an excellent balance of size, power, and cost. It is the go-to choice for CNC routers, small milling machines, and larger 3D printers. Its versatility makes it suitable for a wide range of industrial automation tasks.

NEMA 34 High Torque Stepper Motor: When substantial power is required, this large frame stepper motor is the next step up. It is designed for heavy-duty CNC machines, industrial gantries, and automation systems that must move significant loads. These motors are essential for applications where high thrust force is needed, such as in large-format printing machinery.

Geared Stepper Motor: This type integrates a planetary gearbox with a standard hybrid stepper motor. The gear reduction multiplies the output torque significantly while decreasing the output speed, creating an exceptional low RPM high torque motor. This is ideal for applications like conveyor drives, valve actuators, and any system requiring high force at slow, controlled speeds.

Waterproof Stepper Motor (IP65/IP67): Designed for harsh environments, an IP65 high torque stepper motor is dust-tight and protected against water jets, making it suitable for food and beverage processing, packaging machinery, and outdoor applications. An IP67 rated outdoor stepper motor offers even greater protection against temporary immersion, perfect for solar tracker systems or agricultural equipment.

Closed Loop High Torque Stepper Motor: This advanced system combines a high torque stepper motor with an integrated encoder. The encoder provides real-time feedback to a specialized driver, creating a closed loop system that can detect and correct for missed steps. This technology offers the simplicity of a stepper motor with the reliability and high-speed performance of a servo, ideal for mission-critical medical equipment and high-throughput pick & place machines.

High Torque Stepper Motor with Integrated Encoder and Gearhead: This represents a highly engineered solution that packages a motor, a gearhead for torque multiplication, and an encoder for positional feedback into a single unit. This motor with integrated encoder and gearhead simplifies design and installation for complex motion tasks, providing high torque, low speed, and control assurance in a compact package for applications like robot arms and automotive actuators.

Ultra-Precision Stepper Motor: These motors are engineered for applications requiring the utmost accuracy and smoothness, such as in medical device manufacturing or laboratory automation. They often feature very fine step angles and are optimized for minimal vibration and noise, qualifying as a low noise stepper motor for lab automation.

Certified Stepper Motor for Regulated Industries: Motors used in medical, aerospace, or public-facing equipment often require formal certifications. A stepper motor with CE / UL / RoHS certifications demonstrates compliance with international safety, environmental, and electromagnetic compatibility standards, which is a prerequisite for many medical device and consumer-facing applications.

Custom High Torque Hybrid Stepper Motor: For applications with unique mechanical, electrical, or environmental constraints, a custom high torque hybrid stepper motor may be the only solution. Suppliers can modify standard designs with special shaft sizes, connectors, windings, coatings, or magnetic materials to meet exact performance and form-factor requirements.

Achieving the rated performance from a high torque stepper motor is entirely dependent on pairing it with the correct drive electronics. The motor itself is a passive device; the driver and power supply determine how effectively it converts electrical energy into mechanical motion.

Stepper Motor Drivers are the critical link between a control signal and the motor. They take low-power step and direction pulses from a motion controller and translate them into the high-power current needed to drive the motor windings. For high torque stepper motors, the choice of driver technology is paramount. Basic drivers operate in full-step or half-step modes, which can be sufficient for some applications but often lead to noticeable vibration. Microstepping drivers are highly recommended. They electronically divide each full step into smaller microsteps, resulting in significantly smoother motion, reduced audible noise, and improved low-speed stability. The ability of a driver to deliver a consistent current is vital for maintaining torque, especially at higher speeds.

Power Supplies must be selected with care. The power supply voltage should be significantly higher than the motor’s rated voltage to overcome the back EMF generated at speed. A common rule of thumb is to use a supply voltage 5 to 20 times the motor’s rated voltage, as long as the driver’s maximum voltage rating is not exceeded. The power supply must also be capable of delivering the current required by the motor. The current rating (in Amps) of the supply should be at least equal to the sum of the current required by all motors being driven, though a margin is advisable for peak demands.

Control Signals are the digital commands that dictate motion. The vast majority of modern stepper drivers use a simple two-signal interface: STEP and DIRECTION. Each pulse on the STEP line commands the motor to move one increment (a step or microstep). The frequency of these pulses determines the motor’s speed. The level (high or low) on the DIRECTION line determines the rotational direction. This simplicity makes controlling a high torque stepper motor straightforward for microcontrollers and PLCs.

Wiring and Connections must be executed properly to ensure reliability and prevent damage. Using wires of an adequate gauge is essential to handle the motor’s current without excessive voltage drop or heating. Connections to the driver should be secure, and it is good practice to use shielded cables for the STEP and DIRECTION signals to protect them from electrical noise, which can cause erratic motor behavior. Proper grounding of the driver, power supply, and motor frame is also critical for stable operation.

Even with a properly selected high torque stepper motor and drive system, issues can arise during operation. Understanding the root causes of common problems is essential for maintaining system reliability and performance.

Motor Stalling is one of the most frequent issues. It occurs when the torque demanded by the load exceeds the torque the motor can produce at a given speed. The primary cause is an incorrect match between the motor’s capability and the application’s requirement, often revealed by the stepper motor speed vs torque curve. Stalling can also be caused by insufficient electrical supply. An under-sized power supply that cannot provide adequate voltage will cause a rapid torque drop-off as speed increases. Similarly, a driver set to a current limit below the motor’s rating will prevent the motor from generating its full torque. Solutions include recalculating torque requirements with a larger safety margin, selecting a motor with a higher torque curve, increasing the supply voltage within the driver’s limits, or correctly configuring the driver’s current output.

Overheating is a natural characteristic of stepper motors, as they draw current even when stationary. However, excessive heat can degrade insulation and shorten the stepper motor lifecycle. The most common cause is operating the motor at or near its maximum current rating for extended periods. Using excessive current to achieve more torque than the motor is designed for will generate heat. Other causes include a high step rate at low speeds where torque production is high, or inadequate cooling in the application environment. To mitigate overheating, ensure the driver’s current is set appropriately—often to the motor’s rated current—and not unnecessarily high. Improving airflow around the motor or adding a heat sink can be effective. For continuous-duty applications requiring high torque, selecting a motor with a higher torque rating than strictly necessary will allow it to run cooler.

Vibration and Noise are inherent to the discrete step nature of stepper motors, but they can become problematic in precision applications. These issues are most pronounced at low speeds and at the motor’s resonant frequencies. Vibration can lead to premature mechanical wear and reduce positioning accuracy in sensitive systems. The primary solution is the use of microstepping drivers, which smooth the motion between full steps, significantly reducing vibration and audible noise. Mechanically, ensuring the motor is securely mounted and properly coupled to the load can dampen vibrations. If resonance at specific speeds is an issue, the control system can be programmed to accelerate through those speeds quickly rather than operating steadily within them.

Inaccurate Positioning in an open-loop stepper system almost always indicates lost steps. This happens when the motor fails to move to a commanded position because the load torque exceeded the available motor torque. The system is unaware of the error, leading to an accumulating positional drift. The root cause is often insufficient torque, similar to stalling. However, it can also be caused by sudden shock loads or excessive acceleration rates that demand instant torque beyond the motor’s capability. To prevent inaccuracy, the initial motor selection must be verified against the torque curve. For applications where missed steps are unacceptable, the most robust solution is to transition to a closed loop high torque stepper motor system. This system uses an encoder to monitor position and will automatically correct for any missed steps, ensuring the accuracy of a stepper with the reliability of a servo.

The field of high torque stepper motors is not static; it is evolving to meet the demands of increasingly sophisticated automation and precision engineering. Several key trends are shaping their future development.

Advancements in motor materials and design are leading to continuous improvements in power density. The use of higher-grade permanent magnets, such as neodymium, and improved lamination steels for the stator and rotor cores, allows manufacturers to extract more torque from a given frame size. This trend towards miniaturization without sacrificing performance enables the design of more compact and powerful machinery. Research into new magnetic materials and optimized electromagnetic geometries promises further gains in efficiency and torque output.

Integration with advanced control systems is a dominant trend, largely driven by the rising adoption of closed loop technology. The distinction between stepper and servo systems is blurring as stepper motor with encoder solutions become more cost-effective and widespread. Future drivers will feature more sophisticated algorithms that not only correct for position errors but also actively damp vibrations and optimize current consumption in real-time based on the load. This intelligent control maximizes the motor torque available while improving smoothness and efficiency.

The increasing demand for energy-efficient high torque motors is influencing design priorities. As sustainability becomes a core engineering concern, there is a push to reduce the inherent energy consumption of stepper motors, which typically draw full current even at standstill. New driver technologies are emerging that can dynamically reduce the motor current when full holding torque is not needed, significantly cutting power usage and heat generation without compromising performance. This is particularly important for battery-operated applications and large-scale industrial installations where energy costs are significant.

High torque stepper motors are a critical enabling technology for a vast spectrum of modern applications that demand a combination of precise positional control and substantial mechanical force. From the articulated joints of robot arms to the powerful drives of CNC routers and the reliable actuators in medical equipment, these motors provide a unique solution that balances performance, simplicity, and cost-effectiveness.

The effective selection and use of a high torque stepper motor hinge on a thorough understanding of the application’s requirements, particularly the torque needed across the entire operating speed range. Careful consideration of factors such as motor size, electrical specifications, and environmental conditions is essential. Furthermore, achieving optimal performance is impossible without pairing the motor with a correctly matched driver and power supply.

1. Introduction: Deconstructing AC Induction Motor Horsepower The AC Induction Motor is one of the m...

READ MORE1. Introduction In modern industrial automation, data center construction, consumer electronics upgr...

READ MOREStepper motors represent a cornerstone of modern motion control, offering precise positioning and re...

READ MOREThe industrial motor landscape is undergoing a significant transformation, driven by the relentless ...

READ MORE